The heating zone of reflow soldering is the key to ensuring the stability of the effect

Release time:2023-12-08Publisher:Jeenoce

Individually adjustable heating zone, highly replicable temperature curve, specially designed nozzle, lower lateral temperature difference Δ T. More stable welding processes and lower maintenance costs - JEENOCE's reflow soldering system provides a foundation for achieving optimal welding results with its optimized thermal conductivity, while also meeting the process requirements of various electronic component production processes.

In the reflow soldering system, the nozzle area has a special geometric shape, and the airflow temperature and flow rate in the top and bottom heating areas can be adjusted separately, ensuring that the heating of the components is more complete and uniform.

In addition, due to the infinite variation of transmission speed, the temperature of the curve will also be affected. In order to avoid such situations, the goal is to find an optimal balance setting that can prevent small components from overheating, while large components can be heated thoroughly enough to ensure more optimized welding reliability.

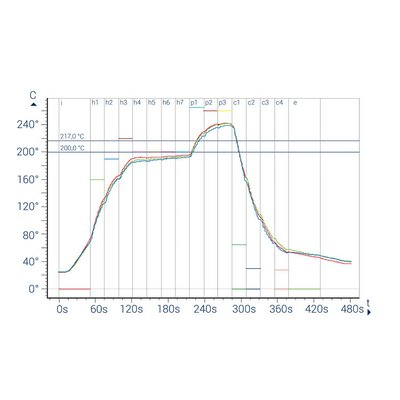

The excellent performance of JEENOCE's reflow soldering system in the field of heat conduction enables it to achieve high replication accuracy of temperature curves (including saddle shaped or linear temperature curves) without obstacles, achieving better welding results. Usually, the corresponding temperature curve can be selected based on the solder paste used.

Saddle shaped temperature curve

When using a saddle shaped temperature curve for heating, the component is first heated to the desired temperature in the preheating zone. At this temperature (saddle), the solder paste begins to melt, and the temperature of components with different thermal masses tends to be consistent. Then complete the welding process within the peak area.

Linear temperature curve

When using linear curves, components are not heated in a stepped manner, but are heated at almost identical temperature slopes. A linear temperature curve can shorten the cycle time and eliminate welding defects such as component erections.

Through the internal circulation system of reflow soldering, the process gas is extracted from the side of the preheating zone and peak zone, purified, and re injected into the furnace to participate in the process circulation. In order to create a stable thermodynamic state in the system and minimize external energy loss, reflow soldering has taken more effective insulation measures between the process furnace and the outer wall.