Industrial CT resolution - spatial resolution and density resolution

Release time:2023-12-08Publisher:Jeenoce

At the beginning of this century, the scientific community and the public selected the greatest scientific inventions of the 20th century, many of which have deeply influenced public life, such as television, transistors, the Internet, and so on. However, there is one great invention that many people are not very familiar with, which is CT scanning technology.

In 1963, American physicist Cormac discovered that the transmittance of X-rays was different and derived some calculation formulas; In 1967, British electronic engineer Hensfield developed a simple scanning device, later known as CT, that could enhance X-ray radiation sources for experimental scanning measurements of human heads. In September 1971, Huntsfield collaborated with a neuroradiologist to examine the first patient, and the experiment was very successful. In April 1972, Huntsfield first announced this result at the British Radiology Annual Conference, officially announcing the birth of CT.

At first, CT technology was mainly applied in the medical field, but soon, engineers realized that CT technology also had great potential in industrial testing. So, the United States was the first to introduce it into the aerospace and other industrial sectors, and other developed countries followed suit. After a short period of time, another branch of CT technology - industrial CT - was formed, and its important role was evaluated as a major technological breakthrough in the field of non-destructive testing.

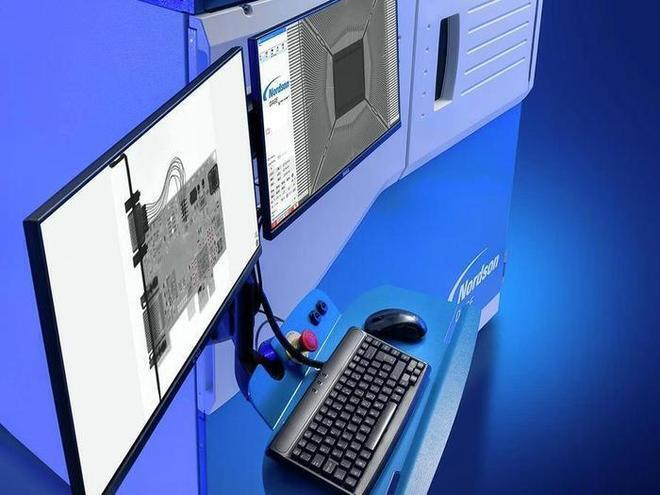

With decades of development, the application of industrial CT has almost spread to all industrial fields, such as automobiles, electronics, aerospace, etc.

Industrial CT and medical CT have the same basic principles and functional components, but there are significant differences in technical indicators and system structures due to different detection objects. The object of medical CT detection is the human body, which is single and definite. The performance indicators and equipment structure are relatively standardized and suitable for mass production. The object of industrial CT detection is industrial products, which vary greatly in shape, composition, size, and weight, and have different measurement requirements, resulting in technical complexity and structural diversity, with strong specificity.

The reason why CT technology is considered one of the greatest technological achievements of the late 20th century is that it is not affected by factors such as the material, shape, and surface condition of the object being tested. It can provide two-dimensional and three-dimensional intuitive images of the object being tested, and has become an important means of medical testing or non-destructive testing and quality evaluation of industrial equipment or components.

The spatial resolution of CT systems is an important performance characterization parameter and a key factor in ensuring the quality of CT detection. Spatial resolution refers to the ability to distinguish specific minimum geometric details from CT images, quantitatively expressed as the minimum distance between two detail features. In medical clinical practice, it is reflected in the imaging ability of small lesions or structures, while in industrial CT, it is reflected in the ability to distinguish detail features (pores, cracks). The modulation transfer function is used to test the spatial resolution of the industrial CT imaging system, which can be defined as the amplitude of the boundary response function Fourier transform. Usually, two test methods are used to test the modulation transfer function in the industrial CT system and draw the MTF curve, namely, the disk method and the line to card method.

In addition to spatial resolution, contrast resolution is also two indicators for evaluating CT performance and demonstrating image quality. Spatial resolution refers to the minimum detail that can be displayed in an image when the density resolution is greater than 10%; Density resolution refers to the ability to distinguish the minimum density difference between tissues. The two are mutually restrictive. The spatial resolution is closely related to the pixel size, generally 1.5 times the pixel width. The smaller the number of pixels, the higher the spatial resolution, and the clearer the image. However, under the condition that the total energy of the X-ray source remains constant, the number of photons obtained per unit volume decreases proportionally, resulting in a decrease in density resolution. The density resolution of CT is also constrained by noise and the size of the display object. The smaller the noise and the larger the display object, the better the density resolution.

Spatial resolution is the ability of detection equipment to distinguish small objects. The higher the spatial resolution, the clearer the interface between different objects in the detected image, and the smaller the minimum feature size that can be distinguished.

Density resolution is the ability of a device to distinguish different objects. The higher the density resolution, the more obvious the differences between different objects in the detection image, and the stronger the ability to distinguish different substances.

The main factors affecting density resolution are signal-to-noise ratio, pixel size, and detail feature size. The main sources of noise are quantum noise from radiation sources, electronic component noise, and noise reflected in images caused by reconstruction algorithms. Quantum noise is the main factor. The relationship between it and the dose of the radiation source is calculated using Brooks formula. To improve density resolution, the dose of the radiation source needs to be increased. When the size of detail features is smaller than the minimum beam width, the density resolution is directly proportional to the noise and pixel size, and inversely proportional to the minimum beam width; When the size of detail features is greater than or equal to the minimum beam width, the density resolution is directly proportional to the noise and pixel size, and inversely proportional to the size of detail features. The density resolution is related to the detailed feature size of the detected object. To improve the density resolution of the system, it is necessary to reduce image noise and sampling interval, lower the density resolution value, and improve the density resolution.

Reducing spatial resolution can achieve higher density resolution when detecting samples with detail feature sizes smaller than the minimum beam width. When the size of detail features is greater than or equal to the minimum beam width, improving spatial resolution and density resolution are not contradictory, that is, using high spatial resolution parameters for detection does not affect the resolution of the density of the detected object.

In summary, the main factors affecting the spatial resolution of CT systems are spatial frequency (i.e. sampling interval or pixel size) and the operational accuracy of the system. The smaller the sampling interval, the higher the pixel size of the CT image, and the stronger the spatial resolution ability of the image. This requires high operational accuracy to ensure accurate positioning during the data sampling process.