How to clean the glue dispenser?

Release time:2023-12-08Publisher:Jeenoce

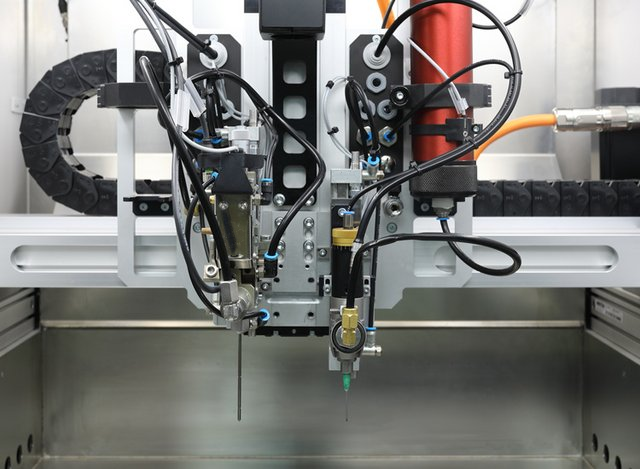

The automatic glue dispenser may clog during glue filling, reducing the amount of glue, affecting the efficiency of glue filling, or causing mixing errors that affect the quality of glue filling. Or if the glue cannot be directly distributed, so the machine cannot be used, how can we avoid blockage of the automatic glue dispenser?

The mixing pipe of the glue dispenser is blocked. The reason for this phenomenon may be that the glue was temporarily stopped in the middle, the anti curing function was not turned on, and the glue dried in the mixing tube. It is also possible that employees forget to clean the mixing tube after work, causing the remaining glue in the mixing tube to completely solidify, resulting in blockage. The method to prevent this blockage is actually very simple. If employees need to leave for a short period of time, such as ten minutes, twenty minutes, or half an hour, turn on the anti curing function of the automatic glue dispenser. If it is after work time, directly turn on the automatic cleaning function to clean the glue inside the mixing tube.

The glue dispenser pipeline is blocked. The reason for this phenomenon may be that there is too much filling material in the glue, which settles in the pipeline. A better way to solve this problem is to replace it with a better glue. If you don't want to change the glue, you can put a filter on the funnel and filter it when pouring the glue.

3. The material bucket of the glue dispenser is blocked, and if it is not used for a long time, some glue will dry in the bucket. Some customers may only replenish the glue once a month or two to three months due to the order. If the glue is left in the bucket for a long time, it will dry out. Therefore, for this situation, estimate the amount of glue to be used each time, and clean the bucket in the automatic glue dispenser after filling it up.

4. Crystallization blockage, some adhesive curing agents can absorb water and cause crystallization, such as polyurethane adhesive. If this glue is used, it would be better for the machine to be used more frequently. Don't leave it for too long, as polyurethane adhesive will absorb moisture if left for too long. If used continuously, the glue can remain fresh and reduce crystallization. If the factory conditions are good, nitrogen gas can be filled into the barrel, which is a protective gas and has a particularly good effect on solving glue crystallization.

There are three main methods for cleaning glue in a glue dispenser:

1. Traditional cleaning methods. Clean the head of the mixture with volatile solvents such as dichloromethane and dimethylformamide. This method is both thorough and inexpensive, but the problem is that it will pollute the environment. Due to the volatility, toxicity, and non recyclability of the selected chemicals, which go against the current trend of promoting green environmental protection, their use is limited and gradually accepted by the market and phased out.

2. This is cleaned with high-pressure water. Although this method is non-toxic, low-cost, and easy to operate, there is a common problem of incomplete cleaning in industry. At the same time, high-pressure water cleaning wastes water resources and generates a large amount of industrial wastewater, which is not a good cleaning method.

3. Clean with environmentally friendly circulating solvents. From a social perspective, this method is recommended as environmentally friendly, recyclable, and has good cleaning effects. But as a business, due to high costs and the need for equipment and independent systems, it is often difficult for enterprises to accept. At present, there is no cleaning method that is both environmentally friendly and cost-effective. Therefore, professional cleaning companies should increase their research and development efforts, actively innovate, and strive to develop cheap and environmentally friendly cleaning products as soon as possible to promote the development of the glue filling machine industry.