Analysis of the characteristics and precautions of UV glue dispensing machine

Release time:2023-12-11Publisher:Jeenoce

UV adhesive has superior characteristics that are different from other traditional adhesives, mainly reflected in the following points:

1、 UV glue requires UV light irradiation to cure;

2、 The curing speed of UV adhesive is easier to control compared to other traditional adhesives;

3、 UV glue has good volatility;

4、 UV glue has the characteristics of energy conservation and environmental protection;

5、 UV glue has good insulation, solvent resistance, and high temperature resistance characteristics;

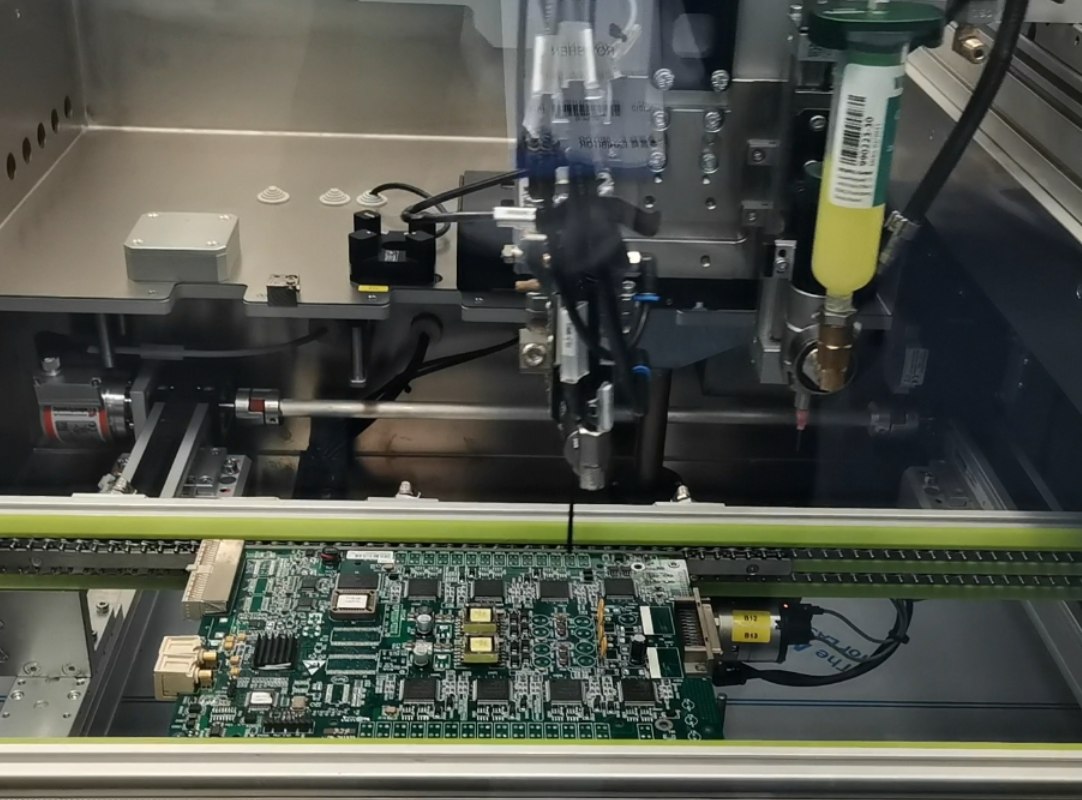

So what are the special features of UV glue automatic dispensing machines? UV glue, with its superior characteristics, uses UV glue automatic dispensing machines for dispensing operations, greatly improving the production efficiency of the production line and ensuring product quality while ensuring production processes, greatly reducing the factory's manpower investment. There are several points to pay attention to when using the UV glue automatic dispensing machine:

1. Needle size: Different needles should be selected for dispensing different sizes of products, which can ensure the quality of the adhesive points and improve production efficiency. When selecting in practice, the size of the inner diameter of the needle should be about half of the diameter of the dispensing point;

2. The size of the dispensing amount: When setting the dispensing amount, this standard is generally used to judge, and the size of the dispensing point diameter is about half of the product spacing for debugging. This ensures that there is sufficient glue to bond the components while avoiding excessive glue. The amount of glue is set based on the dispensing time, and in practice, the dispensing time should be selected according to the production situation (room temperature, adhesive viscosity, etc.).

3. Glue dispensing pressure: The UV glue automatic dispensing machine provides a certain pressure to the needle (glue gun) to ensure the supply of glue, and changes the amount and flow rate of glue by adjusting the pressure. Excessive pressure can easily cause excessive glue, resulting in glue overflow. If the pressure is too low, intermittent dispensing and leakage of glue may occur, leading to unqualified products. The pressure should be selected based on the properties of the adhesive and the working environment temperature.

4. The viscosity of glue: The viscosity of glue directly affects the quality of dispensing. High viscosity, small adhesive point, and wire drawing; The viscosity is low, but the adhesive point will be slightly larger and the product will be infiltrated. So when setting the dispensing pressure, choose a reasonable pressure and dispensing speed for different viscosities of glue.