Application of X-RAY X-ray Detection in Internal Defects of LED

Release time:2023-11-28Publisher:Jeenoce

When using X-ray to detect internal defects in LEDs, the following points need to be noted:

1. Equipment selection

Firstly, different models of X-ray equipment should be selected based on the structure of LED chips. Generally speaking, the internal structure of LED chips can be divided into two types: vertical structure and planar structure. Vertical structured LED chips require the use of equipment capable of generating high-energy X-rays to penetrate the interior of the chip. However, flat structured LED chips require the use of equipment that can generate low-energy X-rays to avoid damage to the chip.

In addition, when selecting X-ray equipment, the radiation dose and stability of the equipment should also be considered. To ensure that the equipment can provide stable X-rays and the radiation dose can ensure the detection effect without causing excessive damage to the LED chip.

2. Operating standards

When conducting X-ray testing, it is necessary to strictly follow the operating procedures. Firstly, it is necessary to ensure that the surface of the LED chip is clean and free of obstacles such as dust and impurities. These obstacles can affect the penetration effect of X-rays, leading to inaccurate detection results.

Secondly, when placing LED chips, it is necessary to ensure that the placement direction of the chips is consistent with the radiation direction of the X-ray equipment. This can minimize the scattering and reflection of X-rays during propagation, and improve detection accuracy.

In addition, the parameters of the X-ray equipment should be adjusted according to the size and shape of the LED chip. For example, for larger LED chips, it is necessary to reduce the energy and exposure time of X-rays to avoid excessive damage to the chip.

3. Environmental control

When conducting X-ray testing, environmental factors can also have an impact on the test results. Therefore, it is necessary to strictly control the testing environment. Firstly, it is necessary to ensure that there are no other radiation sources in the testing environment to avoid interfering with the propagation of X-rays and affecting the testing results.

Secondly, it is necessary to control the ambient temperature and humidity. High or low temperatures can affect the performance and stability of LED chips; Excessive humidity can cause LED chips to become damp or damaged. Therefore, it is necessary to control the ambient temperature and humidity within an appropriate range.

4. Data analysis

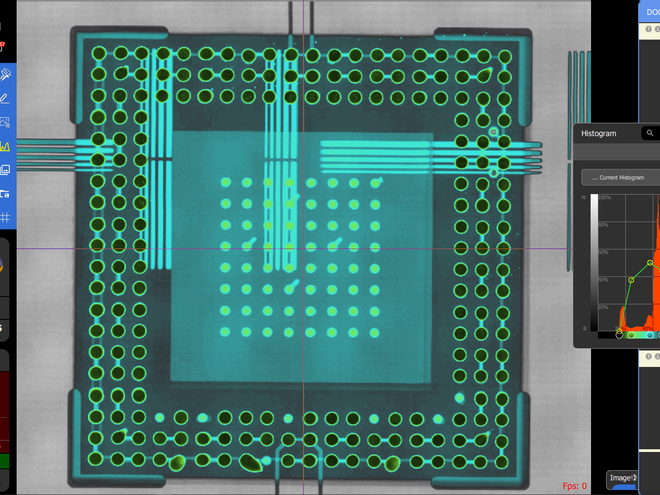

After conducting X-ray testing, a detailed analysis of the test data is required. Firstly, it is necessary to determine whether there are any defects inside the LED chip. By analyzing the detection data, defects such as cracks, pores, and impurities inside the chip can be discovered. For these defects, corresponding measures need to be taken in a timely manner to avoid further damage to the LED chip.

Secondly, it is necessary to summarize and generalize the detection data. By analyzing a large amount of data, the distribution patterns and characteristics of internal defects in LED chips can be discovered. These data can provide valuable references for subsequent production and research and development.

In summary, using X-ray to detect internal defects in LEDs requires attention to the following aspects. Only by strictly adhering to operating standards, paying attention to environmental control and data analysis requirements, can the accuracy and reliability of detection results be guaranteed, thereby providing strong support for the production and research and development of LED chips.