What are the characteristics of piezoelectric spray dispensing valves

Release time:2023-11-28Publisher:Jeenoce

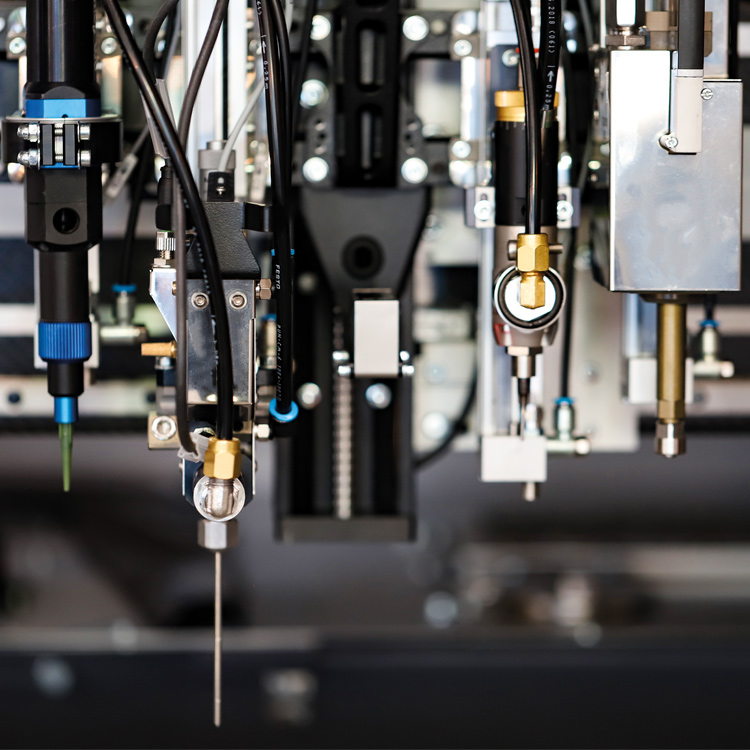

With the needs of industry production, fully automatic dispensing machines have also been widely used in the market, such as in the automotive industry, electronics industry, and electroacoustic industry. Next, let's take a look at the characteristics of the piezoelectric spray dispensing valve of fully automatic dispensing machines.

The working principle of the piezoelectric jet valve of the fully automatic dispensing machine is as follows: the dispensing head maintains a constant distance from the substrate, and the adhesive near the nozzle outlet is forced to achieve a high speed under instantaneous high pressure. It leaves the nozzle, forms droplets and drips, achieving the coating at the target location.

Features of the piezoelectric spray dispensing valve of the fully automatic dispensing machine:

1. Non contact spray coating without Z-axis movement, improving the production efficiency of automatic coating machines.

2. High precision coating.

3. No need for Z-axis movement, the glue spraying speed can reach 300 times per second, improving production efficiency.

4. Applicable fluid viscosity range: 7000 to 2000000 Cps.

5. Exquisite modular design.

6. Easy and fast cleaning.

7. Contact coating can eliminate plating contamination, wire damage, and chip scratches caused by contact between the needle and the target surface.

8. Cost effectiveness.

The fully automatic dispensing electromechanical spraying valve is a non-contact spraying dispensing valve that can be used for various adhesives such as surface mounting adhesive, conductive silver paste, IC packaging adhesive, bottom filling adhesive, sealant, surface coating adhesive, etc., flow control, and high-speed application operation.

The fully automatic dispensing electromechanical spray valve adopts piezoelectric technology to ensure outstanding dispensing accuracy and process control, while achieving high production efficiency. The non-contact spray dispensing method eliminates Z-axis movement, improves productivity, and prevents the needle from touching the workpiece, thereby increasing production.

The fully automatic dispensing electromechanical spray valve has a compact structure, modular design, and spray valve controller, making it easy to carry on the dispensing platform. There are multiple nozzles to choose from to meet different application requirements.