Working principle of reflow soldering furnace

Release time:2023-11-28Publisher:Jeenoce

Reflow soldering furnace is an SMT production equipment used to solder SMT surface mount components onto circuit boards in the SMT process. Reflow soldering furnace relies on the hot air flow inside the furnace to act on the solder paste on the solder joints of the brushed solder paste circuit board, melting the solder paste back into liquid tin, allowing SMT surface mount components to be welded and fused with the circuit board. Then, it is cooled by the reflow soldering furnace to form solder joints, and the adhesive solder paste undergoes physical reactions under a fixed high-temperature airflow to achieve the soldering effect of SMT process.

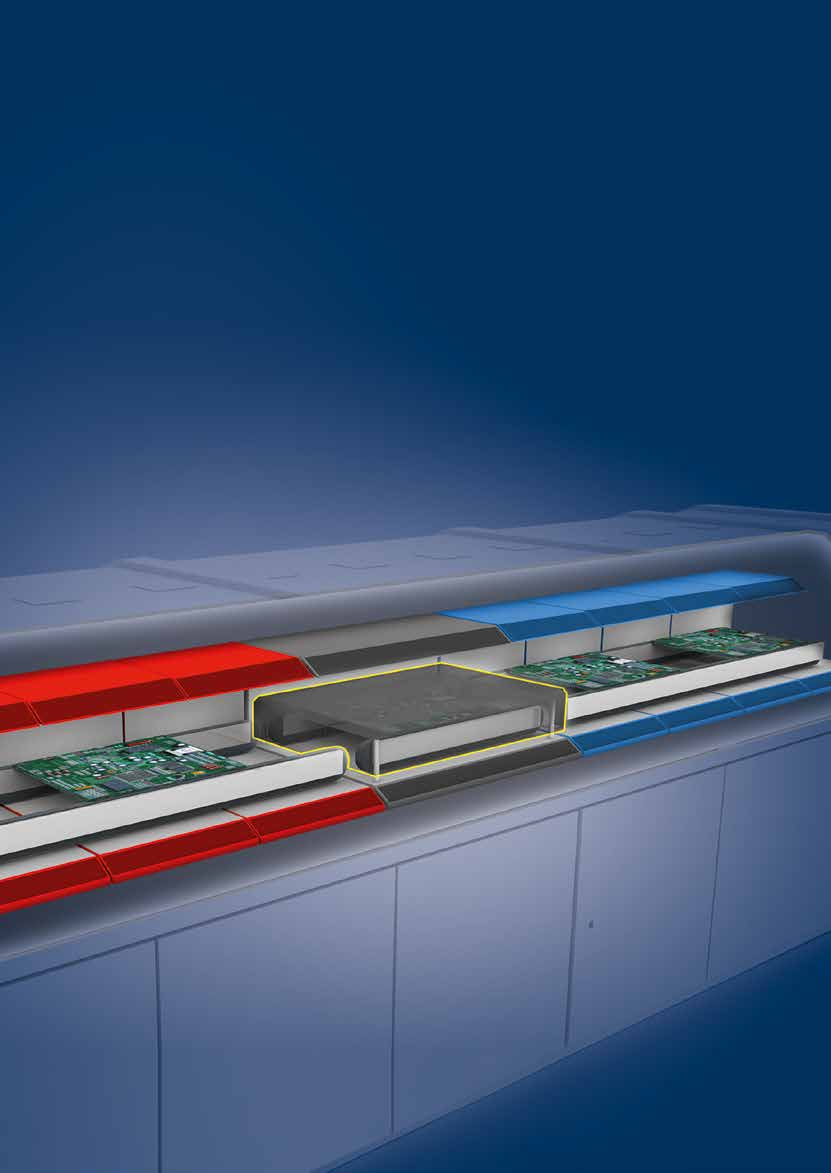

The welding process in the reflow soldering furnace is divided into four stages. The circuit board with SMT components attached is transported through the reflow soldering furnace guide rail, passing through the preheating zone, insulation zone, welding zone, and cooling zone of the reflow soldering furnace. After passing through the four temperature zones of the reflow soldering furnace, a complete solder joint is formed. Below, JEENOCE will explain the principles of the four temperature zones of the reflow soldering furnace separately.

The working principle of the preheating zone of the reflow soldering furnace:

Preheating is a heating behavior carried out to activate the solder paste and avoid rapid high-temperature heating during tin immersion, which may cause component defects. The goal of this area is to heat up the PCB at room temperature as soon as possible, but the heating rate should be controlled within an appropriate range. If it is too fast, it may cause thermal shock, and the circuit board and components may be damaged. If it is too slow, the solvent evaporation will not be sufficient, affecting the welding quality. Due to the fast heating speed, there is a large temperature difference in the reflow soldering furnace in the rear section of the temperature zone. To prevent damage to components caused by thermal shock, a large heating rate of 4 ℃/S is generally specified, and a rising rate of 1-3 ℃/S is usually set.

The working principle of the insulation area of the reflow soldering furnace:

The main purpose of the insulation stage is to stabilize the temperature of various components in the reflow soldering furnace and minimize the temperature difference as much as possible. Give enough time in this area to catch up with the temperature of larger components and ensure that the flux in the solder paste is fully evaporated. At the end of the insulation section, oxides on the solder pads, solder balls, and component pins are removed by the action of the flux, and the temperature of the entire circuit board reaches equilibrium. It should be noted that all components on the SMA should have the same temperature at the end of this section, otherwise entering the reflux section will result in various poor soldering phenomena due to uneven temperatures in each part.

The working principle of the reflow soldering zone in the reflow soldering furnace:

When the PCB enters the reflow zone, the temperature rapidly rises, causing the solder paste to reach a molten state. The melting point of lead solder paste 63sn37PB is 183 ℃, and the melting point of lead solder paste 96.5Sn3Ag0.5Cu is 217 ℃. The temperature of the heater is set high in this area, causing the temperature of the components to rapidly increase. The value temperature of the reflow soldering curve is usually determined by the melting point temperature of the solder, the heat resistance temperature of the assembled substrate and components. The welding temperature in the reflow section varies depending on the type of solder paste used. Generally, the high temperature for lead is between 230-250 ℃, while for lead, it is between 210-230 ℃. Low temperature can easily lead to cold contact and insufficient wetting; If it is too high, the epoxy resin substrate and plastic parts are prone to coking and delamination, and excessive eutectic metal compounds will form, leading to brittle welding points and affecting welding strength. In the reflow soldering area, special attention should be paid to the reflow time not being too long to prevent damage to the reflow soldering furnace, which may also have adverse effects on the performance of electronic components or cause circuit boards to be burnt.

Working principle of the cooling area of the reflow soldering furnace:

At this stage, the temperature is cooled below the solid-phase temperature to solidify the solder joint. The cooling rate will have an impact on the strength of the solder joint. If the cooling rate is too slow, it will lead to the production of excessive eutectic metal compounds and the formation of large grain structures at the welding points, resulting in a decrease in the strength of the welding points. The cooling rate in the cooling zone is generally around 4 ℃/S, and cooling at 75 ℃ is sufficient.

The circuit board that has been coated with solder paste and installed with SMT components is transported through the guide rail of the reflow soldering furnace, and after passing through the four temperature zones above the reflow soldering furnace, it forms a complete soldered circuit board. This is also the entire working principle of the reflow soldering furnace.