What is the reason for the inconsistent glue output during the operation of the glue dispenser?

Release time:2023-11-20Publisher:Jeenoce

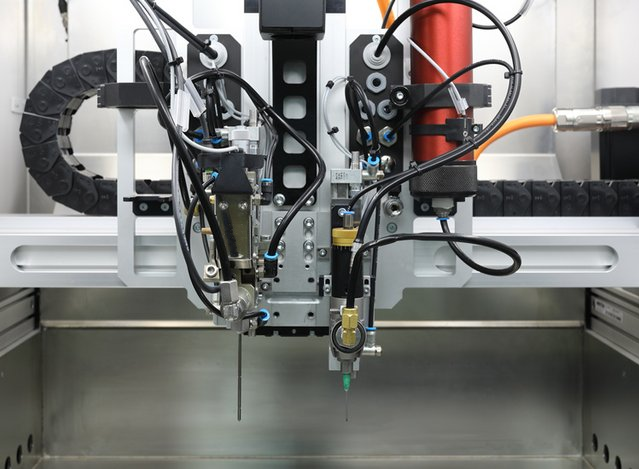

With the needs of production, manufacturing and processing enterprises have also added many different types of automated equipment, such as ab glue dispensers, ab glue dispensing machines, lock screw machines, etc. These equipment are commonly used in fields such as LED, automobiles, sensors, etc. Each type of equipment cannot avoid some small problems during operation. What are the reasons for these problems? Next, let's take a look at the factors that cause inconsistent glue output during the operation of ab glue dispensers.

The amount of adhesive produced by the AB glue filling machine is determined by factors such as glue viscosity, working pressure, gluing time, and the instantaneous cutting performance of the adhesive.

Among the four factors mentioned above, the viscosity of the adhesive varies depending on the raw material of the adhesive. The viscosity range of typical rubber compounds is 1000 to 100000 units. Under constant viscosity, the higher the pressure, the faster the adhesive is discharged. The viscosity and pressure are constant, and the longer the glue supply time, the higher the glue output. The better the instantaneous rupture performance of the adhesive, the higher the yield of the adhesive, reducing delays and wire drawing leakage.

In order to better achieve accurate control of glue output, the glue dispenser needs to ensure accurate pressure regulation, accurate timing execution, and excellent glue cutting performance.

Regardless of whether the pressure adjustment of the AB glue filling machine is accurate, it is first necessary to correctly handle the relationship between the adhesive viscosity and the working pressure of the pneumatic valve. Generally speaking, the higher the viscosity, the lower the fluidity. Only by establishing a proportional relationship between the CPS value of viscosity qualitative analysis and the working pressure value of the pneumatic valve can the constant flow rate of the adhesive be ensured and the total flow rate of the adhesive be controlled.

Additionally, be careful when adjusting the pressure of the AB glue dispenser. When the working pressure increases to a certain extent, the discharged adhesive water will generate relative impact force on the product workpiece. If the impact force exceeds a certain level, it may cause impact splashing due to recoil. Therefore, a suitable range of working pressure values can not only ensure that the adhesive does not splash, but also achieve faster adhesive application under the conditions that workers' professional skills and other production conditions can achieve, which can improve work efficiency.

In the AB glue filling machine, due to the wide variety of adhesives, the parameter for qualitative analysis of adhesive supply is not in volumetric units such as milliliters, but in time units. This is because the time is fixed, and the pressure is adjusted according to the viscosity of the adhesive to achieve a constant speed. The amount of adhesive discharged is also determined, and the accuracy of the glue supply time of the glue dispenser depends on the accuracy of the relay.

If the viscosity of the adhesive is low, it will leak downward under its own force without releasing pressure, and adhesive leakage often leads to inaccurate application of the adhesive.

Therefore, precision joints require solving leakage problems without applying pressure. It is recommended that the adhesive filling machine can use reverse suction technology to provide a suitable negative pressure for the adhesive material. The negative pressure is set on and off. When the positive pressure of the adhesive is cut off, a negative pressure is generated at the same time, which "solves" the delay of adhesive application, timely "retains" the adhesive leakage, and achieves instant adhesive failure.

Overall, there are related factors such as glue viscosity and glue application time for the inconsistent glue output of the AB glue dispenser. The above also introduces a solution. When encountering such problems, you can refer to this article.