How to achieve efficient residue management in reflow soldering equipment

Release time:2023-11-17Publisher:Jeenoce

For reflow soldering systems, the soldering process is not just about the melting process of solder paste. When welding highly complex electronic components, a stable and reliable cooling process is the key to achieving the best soldering effect. JEENOCE's reflow soldering system integrates filter monitoring and flow control functions, ensuring effective residue management and stable cooling performance, thereby providing a stable and safe process environment for welding.

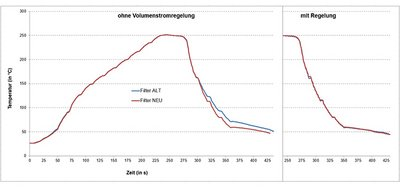

During the melting process of solder paste in the furnace, a portion of process gas will be generated, causing pollution to the cooling module and filter, resulting in limited or reduced volume flow during the cooling process (which should be kept as constant as possible), resulting in insufficient gas flow through the filter. At the same time, less gas means lower cooling capacity, which may lead to an increase in outlet temperature or a change in component cooling gradient. To ensure the safety and stability of the welding process, correct outlet temperature and constant cooling gradient are crucial for welding components.

When the automatic filter monitoring system with active adjustment function automatically detects through the integrated control system that the flow rate is lower than the level set by the customer separately to meet their production requirements, this indicates that the filter needs to be replaced immediately. Prior to this, the system automatically adjusted the volume flow rate through active adjustment to continue cooling the components within the specified process window by increasing cooling capacity. The gas flow rate set for this cooling zone is continuously compared with the actual value.

Actively adjusting the filter monitoring system not only ensures high reliability of the process, but also ensures that the reflow soldering process achieves optimal results in a constant current state. In addition, external data analysis programs can be used to collect monitoring data for actively adjusting filters, which can be used to predict the next filter replacement.