Discussion on the Classification of Industrial CT Ray Tubes

Release time:2023-11-20Publisher:Jeenoce

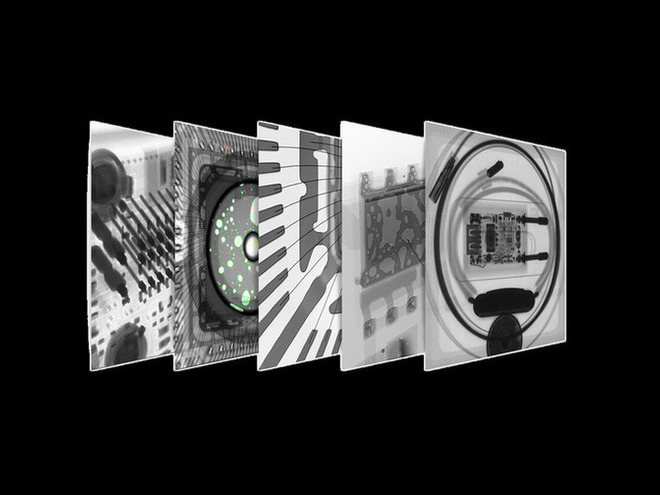

Industrial CT (computed tomography) is an important non-destructive testing and three-dimensional imaging technology widely used in manufacturing, materials science, and other fields. In industrial CT systems, ray tubes are one of the key components that generate a beam of radiation for imaging. In different application scenarios, industrial CT ray tubes are classified based on their characteristics and uses. This article will introduce four main classifications of industrial CT ray tubes: microfocal spot ray tubes, nanofocal ray tubes, small focal ray tubes, and high-speed ray tubes.

Microfocal Spot Ray Tube and Nanofocal Ray Tube

The micro focal point line tube produces a ray beam with a very small focal size, usually at the micrometer level. This type of ray tube is specifically designed for applications that require high-resolution imaging and is suitable for the detection of small parts, fine structures, and thin materials. It can display smaller details inside objects.

Nanofocal ray tubes are further developed on the basis of microfocal ray tubes, resulting in smaller beam focal sizes, usually at the nanoscale. This type of ray tube is suitable for high-resolution imaging of small samples or nanoscale structures, and has important applications in nanotechnology and material science research, capable of revealing finer structures and features.

Small focus ray tube

Small focus ray tubes are another important classification, although their focal size accuracy is not as high as that of microfocal and nanofocal ray tubes, they still play an important role in practical applications. The size of the beam focus generated by it is between the micro focus and the general focus, which balances resolution and imaging speed to a certain extent. Small focus ray tubes are suitable for imaging medium-sized samples, which can achieve relatively high resolution and also handle relatively larger samples.

Although the resolution of small focus ray tubes is relatively low, their imaging effects are still very valuable in practical engineering and scientific fields. It can obtain imaging results in a short period of time, suitable for the detection and analysis of medium-sized samples, and suitable for a wider range of application needs.

High speed ray tubes and general ray tubes

High speed X-ray tubes are another important type of industrial CT ray tubes. It generates a fast pulsed beam of radiation, suitable for applications that require real-time imaging of dynamic processes. If it is necessary to capture the changes in materials during loading or deformation, or to observe instantaneous processes such as fluid flow, high-speed ray tubes can provide high-frequency imaging and obtain results with high temporal resolution.

On the other hand, a general ray tube usually refers to a traditional ray tube that produces a continuous beam of rays and is suitable for static imaging. This type of ray tube can be used in static imaging fields such as industrial CT scanning and medical X-ray imaging, where the object being imaged does not need to change rapidly during the imaging process.

In industrial CT applications, it is crucial to choose the type of ray tube that is suitable for a specific task. Micro focus (or nanofocus), small focus, and high-speed ray tubes are used for high-resolution imaging and real-time monitoring of dynamic processes, while general ray tubes are widely used in the field of static imaging.