The Composition and Structure of the Visual Splitter

Release time:2023-11-16Publisher:Jeenoce

The advantage of a visual splitter lies in its efficient, accurate, and automated characteristics. It can greatly improve the speed and accuracy of board splitting and classification, reduce the need for manual operations, and improve production efficiency and quality. Visual sorting machines are widely used in fields such as electronic manufacturing, automated production lines, and logistics sorting, and are very suitable for large-scale production and high-precision scenarios.

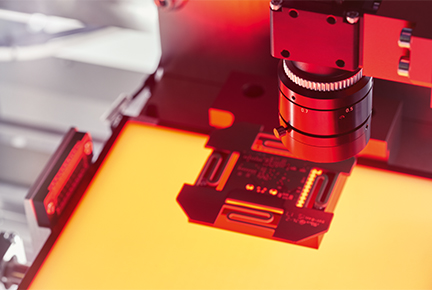

A visual splitter is an automated device used to separate electronic components or other small-sized objects from a large board and classify them. It combines mechanical systems and visual recognition technology, which can efficiently complete the tasks of segmentation and classification.

A visual splitter typically consists of the following components:

1. Feeding system: used to feed large boards containing electronic components or objects into the slitting machine, which can be manually loaded or automatically fed.

2. Visual system: including cameras, light sources, and image processing software, used to capture and process components on the board. Through image processing algorithms, information such as the position, direction, and size of components can be identified.

3. Splitting device: Based on the information provided by the visual system, control the mechanical system for splitting operations. The plate splitting device can use suction cups, robotic arms, conveyor belts, and other methods to separate the identified components from the large plate and place them in corresponding positions or containers.

4. Control system: used to control the operation of the entire dividing machine, including control of the visual system, action control of the dividing device, feedback from sensors, and data processing.