Industrial CT detection equipment: uncovering the mysteries inside objects

Release time:2023-11-16Publisher:Jeenoce

Industrial CT testing equipment plays an important role in modern manufacturing. CT (Computed Tomography) is a computer tomography technique that enables continuous X-ray scanning and image reconstruction of objects to obtain internal structural information in a three-dimensional manner. Industrial CT testing equipment has a wide range of applications in material analysis, defect detection, size measurement, and product verification, and has many advantages.

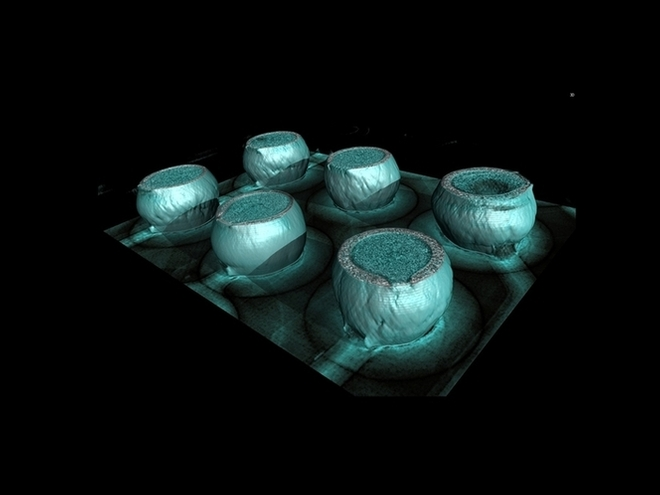

The working principle of industrial CT testing equipment is to use the strong penetration of X-rays to penetrate the tested object from different angles, and the rays pass through the object and are ultimately received by the detector. The device scans continuously from multiple angles to obtain a series of two-dimensional detection images. These images are used for three-dimensional reconstruction through computer algorithms, ultimately generating a three-dimensional model and internal structure image of the object.

The use of industrial CT testing equipment is very extensive. Firstly, it plays an important role in material analysis. Through scanning and reconstruction, the density, microstructure, porosity and other characteristics of materials can be accurately measured and analyzed. This is of great significance for material research, quality control, and product improvement. Secondly, industrial CT testing equipment is also very useful in the field of defect detection. Whether it is metal, plastic, ceramic or other materials, internal or surface defects such as cracks, bubbles, etc. may occur. Through CT detection equipment, these defects can be visually observed and accurate size and shape information can be provided. In addition, industrial CT testing equipment can also be used for size measurement, assembly verification, and non-destructive testing, providing important support for product quality control.

Industrial CT testing equipment has many advantages. Firstly, it can provide high-resolution images that display the details and small defects of objects. Compared to other detection methods such as ultrasonic and magnetic particle testing, CT can provide more intuitive and accurate image information. Secondly, CT detection equipment has strong adaptability to different materials. Whether it is metal, plastic, ceramics, or composite materials, CT testing can be performed. In addition, industrial CT testing equipment has the characteristics of non-contact and non-destructive, and will not cause damage or deformation to the tested object. This is very important in some industries that require high product integrity. In addition, industrial CT testing equipment also has the characteristics of speed and efficiency. Through automated scanning and reconstruction processes, three-dimensional images can be quickly obtained for subsequent analysis and processing.

In summary, industrial CT testing equipment has received widespread attention due to its excellent performance and wide range of applications. It has unique advantages in material analysis, defect detection, dimensional measurement, and product verification. With the continuous development of technology, industrial CT testing equipment will play a more important role in the manufacturing industry, improve product quality, and promote the development of the industry.