What happens if the reflow soldering temperature is too high

Release time:2023-11-15Publisher:Jeenoce

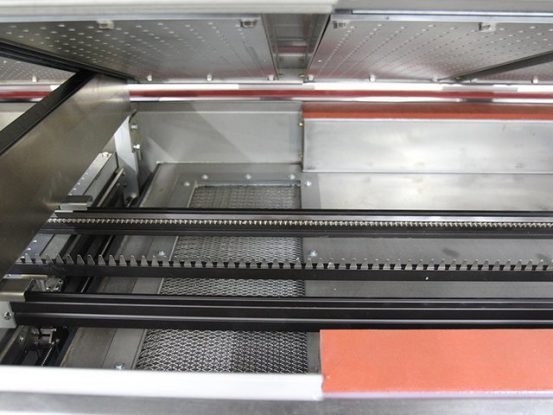

Reflow soldering is a commonly used soldering equipment in electronic manufacturing, mainly used to solder electronic components onto circuit boards. The temperature of reflow soldering has a crucial impact on the welding quality. If the reflow temperature is too high, it may have a negative impact on the welding results.

1. Impact on welding quality: When the reflow soldering temperature is too high, the molten solder at the welding site will become too active, resulting in irregular shape of the solder joints and the formation of poor welding. This situation may lead to poor electrical connectivity, unstable conductivity between components, and even damage to the circuit board.

2. Impact on component performance: Excessive temperature may damage the component itself, especially heat-sensitive components such as LEDs and thermistors. At the same time, high-temperature environments can accelerate the aging process of components and affect their service life.

3. Formation of stress concentration: High temperatures can cause thermal expansion and contraction of materials, which may lead to stress concentration at welding points or circuit boards. In repeated temperature changes, these stresses may lead to fatigue fracture, causing solder joints or circuit boards to fail.

4. Accelerated oxidation: High temperature will accelerate the oxidation process of metals. When an oxide layer is formed on the surface of welding points or other metal components, their conductivity will be greatly reduced.

5. Impact on thermal stability: High temperature environments may alter the thermal stability of materials, resulting in unstable performance of circuit boards or components during temperature changes.

6. Increase energy consumption: In order to maintain a high-temperature environment, more energy is needed, which increases energy consumption and production costs.

7. Increase operational risks: High temperature environments may pose a threat to the safety of operators and require additional safety measures. Therefore, when conducting reflow soldering operations, it is necessary to strictly control the temperature to ensure stable welding quality and component performance.