The widespread application of non-destructive testing equipment

Release time:2023-11-15Publisher:Jeenoce

Non destructive testing has been widely applied in industry, especially online non-destructive testing has been recognized by enterprises. Therefore, using various non-destructive testing technologies to research and develop online non-destructive testing equipment is one of the research projects. In industrial production, not only is the working environment relatively good, but the environment is also slightly poor, accompanied by high temperatures, dust, and water mist. Therefore, different detection equipment should be developed for different industrial occasions in order to perform real-time detection effectively.

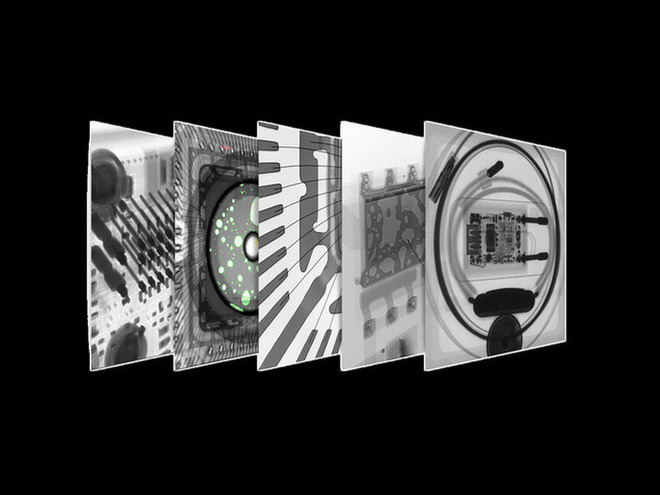

Industrial CT (ICT), a manufacturer of non-destructive testing equipment, is a form of computed tomography or industrial CT imaging. Although the mathematical theory of tomography was first proposed in 1917, it was not until the emergence of computers and their complementarity with radiology that tomography became a new imaging technique. In the industrial field, especially in the fields of non-destructive testing (NDT) and non-destructive evaluation (NDE), industrial CT is considered a good non-destructive testing method in the field of non-destructive testing.

Since the 1980s, major industrialized countries in the world have applied X-ray or gamma ray ICT to non-destructive testing in fields such as aviation, aviation, military, metallurgy, machinery, petroleum, electricity, geology, archaeology, etc. In the 1990s, China gradually applied ICT technology to the field of industrial non-destructive testing. Online non-destructive testing can be applied in industrial production, which can improve the measurement object of rolling accuracy, conduct real-time testing, adjust production equipment in a timely manner, ensure more high-quality rolling material production, effectively improve the production efficiency and qualification rate of enterprises, and bring economic benefits to enterprises at the same time.

The commonly used non-destructive testing methods for X-ray inspection include optical testing, laser testing, image testing, eddy current testing (ECT), radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), and liquid penetrant testing (PT). Other non-destructive testing methods: AE, TIR, LT, ACFMT, MFL, RFT, TOFD, etc.

Non destructive testing is the use of heat, sound, light, and changes in reactions caused by internal structural abnormalities or defects in materials, such as electricity, magnetism, etc., without damaging or affecting the performance of the test object or damaging the internal structure of the test object. Through physical or chemical methods, with the help of modern technology and equipment, the surface and internal structure, properties, inspection, and testing methods of the sample, as well as the type, nature, quantity, shape, position, size Distribution and changes.

Non destructive testing (NDT) is an indispensable and effective tool for industrial development. Non destructive testing equipment manufacturers reflect a country's industrial development level. The importance of NDT has been recognized.