The Combustion Aid for the Development of Lithium Battery Industry - X-ray Equipment

Release time:2023-11-14Publisher:Jeenoce

Since its inception, lithium batteries have quickly become a leader in the battery industry due to their excellent performance. However, due to a series of problems in battery production, the quality of battery products in the market is uneven, and the later cycle life of battery capacity often does not reach the designed service life, affecting user experience. With the gradual expansion of application scope and the increasing volume energy density and capacity of individual batteries.

The testing standards for lithium batteries are mainly examined from three perspectives, namely:

1. Battery safety performance

2. Environmental adaptability

3. Electrical performance

Therefore, in order to adapt to the further development of China's lithium battery industry, improving the production process level of lithium batteries, researching and producing lithium battery manufacturing equipment with independent intellectual property rights have become the requirements for further development of enterprises in the industry. In recent years, with the rapid growth of market demand in the lithium battery industry, lithium battery manufacturers have expanded their production capacity on a large scale, and a group of lithium battery automation production equipment manufacturers with strong research and manufacturing capabilities have emerged in China.

In fact, the problems caused by lithium batteries are closely related to their unique production process.

1. The structure of the battery includes components such as the shell, upper cover, electrode plate, partition, busbar, pole, bridge protection plate, terminal, etc.

2. The production process of lithium batteries can be divided into three stages: the manufacturing of the front electrode, the packaging of the middle electrode, and the activation of the rear battery. The purpose of the battery activation stage is to fully activate the active substances and electrolyte in the battery to achieve stable electrochemical performance. The activation stage includes stages such as pre charging, formation, aging, and constant volume. The purpose of pre charging and formation is to activate the positive and negative electrode materials through the initial few charges and discharges, so that the materials are in the optimal state of use.

If a series of safety hazards such as explosions are caused by internal defects in the manufacturing process or other issues of lithium batteries, the gains are not worth the losses. Therefore, testing the production process of lithium batteries has become a top priority.

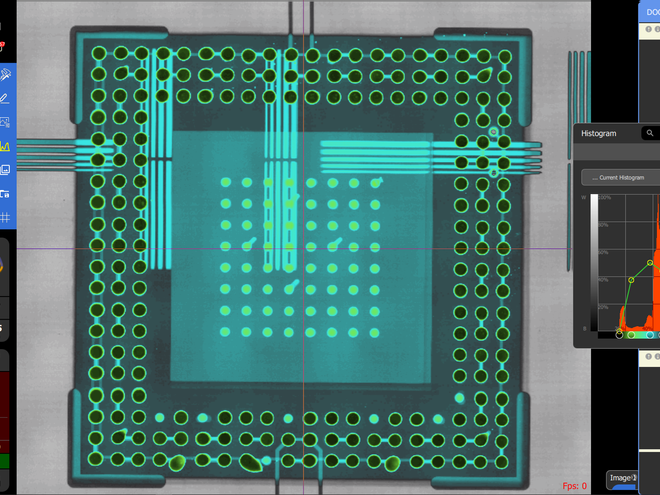

For different battery systems, such as ternary positive electrode/graphite negative electrode lithium batteries, lithium iron phosphate positive electrode/graphite negative electrode lithium batteries, or lithium titanate negative electrode batteries, targeted tests need to be conducted based on material and lithium battery characteristics. The vast majority of lithium batteries are packaged in steel shells, and it is difficult to detect internal quality issues using general methods. At this point, the role of X-Ray testing equipment becomes apparent.