Requirements for shallow reflow solder paste

Release time:2023-11-13Publisher:Jeenoce

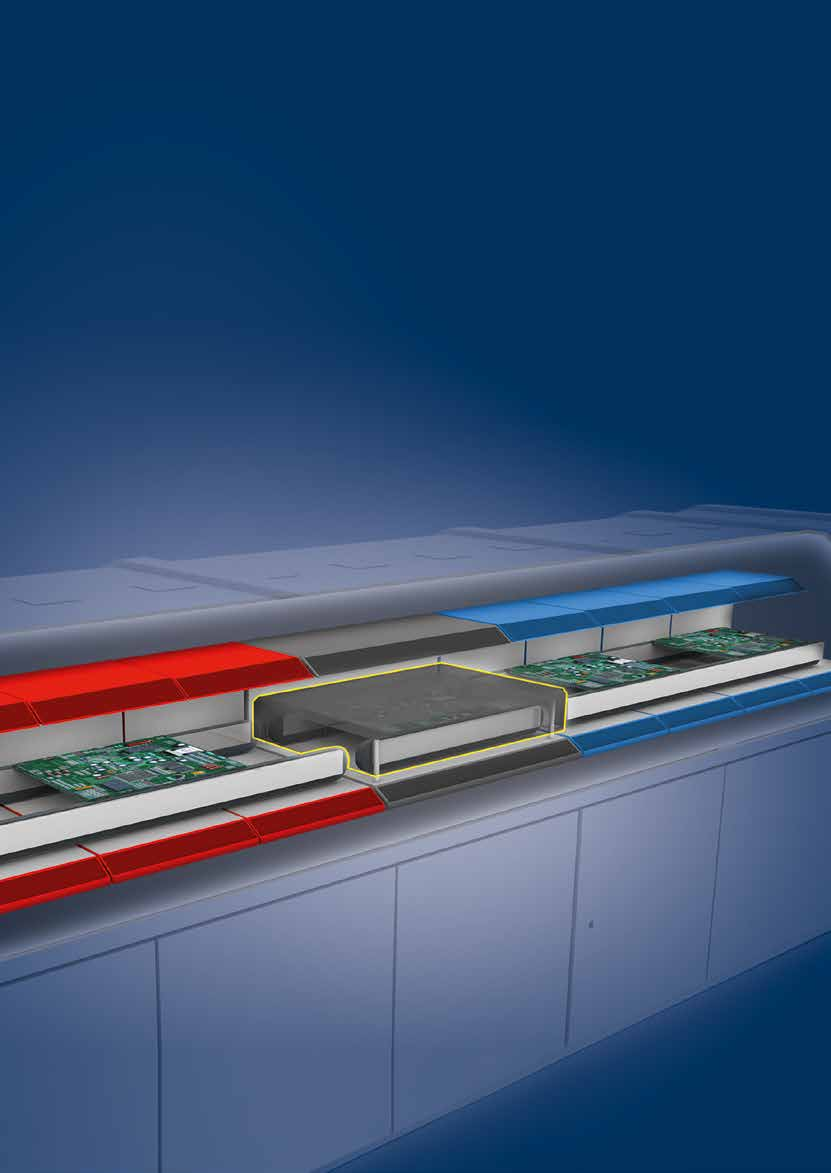

The main function of reflow soldering is to place the circuit board with attached components into the track of the reflow soldering machine. Through heating, insulation, welding, cooling, and other processes, the solder paste is transformed from a paste to a liquid through high temperature, and then cooled to a solid state, thereby achieving the function of soldering electronic components with PCB boards. JEENOCE shares the reflow soldering process requirements for solder paste here.

1. The importance of solder paste reflow welding is to have sufficient slow heating to safely evaporate the solvent, prevent the formation of solder beads and limit the internal stress of components caused by temperature expansion, which can cause reliability issues with fracture marks.

2. Secondly, during solder paste reflow soldering, the active phase of the flux must have appropriate time and temperature, allowing the cleaning phase to be completed when the solder particles have just begun to melt.

3. The melting stage of solder in the solder paste reflow time and temperature curve is important. It is necessary to fully melt the solder particles, liquefy them to form metallurgical welding, and evaporate the residual solvent and flux to form the surface of the solder foot. If this stage is too hot or too long, it may cause damage to the components and PCB.

4. The setting of the solder paste reflux temperature curve is based on the data provided by the solder paste supplier, while grasping the principle of internal temperature stress changes in the components, that is, the heating temperature rise rate is less than 3 ° C per second, and the cooling temperature drop rate is less than 5 ° C.

5. If the size and weight of PCB assembly during solder paste reflow soldering are very similar, the same temperature curve can be used.

6. It is important to regularly and even daily check whether the reflow temperature curve is correct.