What is the general temperature control for reflow soldering?

Release time:2024-07-16Publisher:Jeenoce

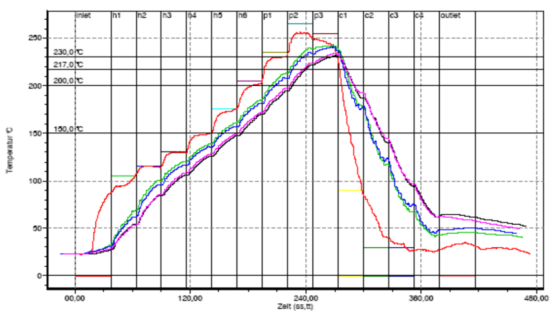

The control of reflow soldering temperature is very important during the reflow soldering process. If the temperature is too high or too low, it will affect the quality and reliability of welding. Generally speaking, the temperature control range for reflow soldering is as follows:

1. Preheating temperature: Before preheating the heating plate to the welding temperature, an appropriate preheating temperature needs to be set. The preheating temperature should be determined based on factors such as the size, shape, and material of the welded components. Generally speaking, the preheating temperature should be above 200 ° C.

2. Welding temperature: When the heating plate reaches the welding temperature, the welding process begins. The welding temperature should be determined based on factors such as the material, size, and welding method of the welded components. Generally speaking, the welding temperature should be between 230 ° C and 260 ° C.

3. Welding time: It is necessary to set an appropriate welding time during the welding process. The welding time should be determined based on factors such as the material, size, and welding method of the welded components. Generally speaking, the welding time is between 2-5 seconds.

4. Cooling temperature: After welding is completed, the welded components need to be cooled to room temperature. The cooling temperature should be determined based on factors such as the material, size, and welding method of the welded components. Generally speaking, the cooling temperature should be below 150 ° C.

It should be noted that different welding components and welding methods may require different temperature and time settings. Therefore, when performing reflow soldering operations, temperature and time adjustments should be made according to the actual situation to ensure soldering quality and reliability.