What are the difficulties in X-RAY testing PCBA for virtual soldering?

Release time:2024-07-16Publisher:Jeenoce

With the rapid development of electronic technology, the complexity and integration of printed circuit boards (PCBs) continue to increase, and the requirements for soldering quality are also increasing. Among them, virtual soldering, as one of the common defects in the PCB assembly process, has a serious impact on the performance and reliability of the circuit board. Therefore, accurate and rapid detection of PCB virtual soldering has become an important issue in the field of electronic manufacturing.

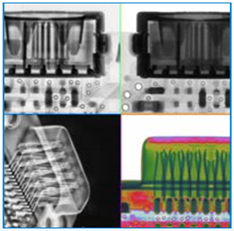

X-RAY testing, as a non-contact non-destructive testing method, plays an important role in PCBA virtual soldering detection, but also faces a series of difficulties.

Firstly, there are various definitions and manifestations of PCBA virtual soldering, which poses challenges for X-ray inspection. Virtual soldering refers to the failure of solder joints to form effective electrical or mechanical connections during the soldering process, resulting in unstable or ineffective electrical performance of the circuit board. The manifestations of virtual soldering include incomplete solder joints, gaps between solder and solder pads, and poor solder wetting. These complex and varied forms of expression make it difficult for X-ray detection to identify virtual welding defects.

Secondly, the structural characteristics of PCBA also pose difficulties for X-ray inspection. Due to the wide variety and compact layout of components on PCB boards, as well as high solder joint density and small spacing, X-RAY detection equipment faces challenges when penetrating PCB boards and obtaining clear images.

In addition, the packaging materials of some components have strong absorption and scattering effects on X-rays, which also affects the effectiveness of X-ray detection.

Furthermore, the resolution and sensitivity of X-RAY detection equipment have a significant impact on the results of virtual welding detection. Due to the fact that virtual soldering defects are usually small and may be hidden inside the solder joint or between the solder pad and the solder, detection equipment with high resolution and sensitivity is required to accurately identify them. However, improving resolution and sensitivity often means increasing detection costs and technical difficulties, which also limits the widespread application of X-ray detection in PCBA virtual soldering detection.

In addition, the X-RAY detection process may also be affected by other factors, such as the skill level of the operator, which directly affects the accuracy and reliability of the detection results.

To address the above difficulties, a series of measures can be taken to improve the accuracy and efficiency of X-RAY detection in PCBA virtual soldering detection. For example, optimizing the parameter settings of detection equipment to improve resolution and sensitivity; Adopting advanced image processing techniques to filter and enhance the acquired images, in order to improve the recognition rate of virtual welding defects; Strengthen the training and management of operators, improve their skill level and sense of responsibility; At the same time, combined with other detection methods such as infrared thermography, ultrasound detection, etc., a multi tool collaborative detection mode is formed to further improve the detection effect and reliability.