What is the function of reflow soldering furnace

Release time:2024-07-05Publisher:Jeenoce

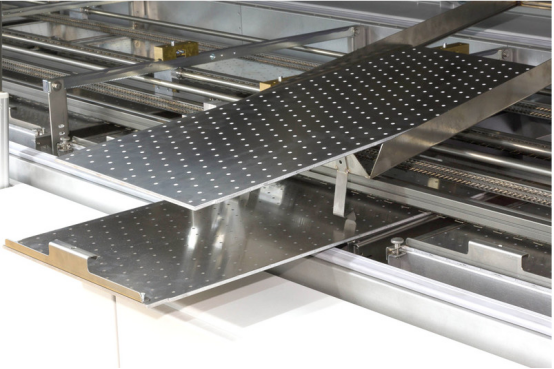

Reflow soldering furnace is a commonly used soldering equipment in the manufacturing process of electronic components. Its function is to solder pre installed electronic components such as chips, capacitors, resistors, etc. together with printed circuit boards (PCBs) after heating and pressure, forming a complete electronic component. JEENOCE shares that the functions of reflow soldering furnaces include the following aspects:

1. Heating: The reflow soldering furnace can heat the PCB board to a high temperature state, usually between 250 and 350 ° C, so that the electronic components can reach a melting state and complete the soldering process.

2. Pressure: During the heating process, the reflow soldering furnace will control the pressure and temperature to make the fusion between electronic components and PCB boards more secure, ensuring welding quality.

3. Quality control: The reflow soldering furnace can monitor and control the welding process in real time, ensuring that the welding quality meets the requirements.

4. Production efficiency: Reflow soldering furnaces can quickly complete the welding of electronic components, improving production efficiency and output.