Calibration methods and precautions for automatic dispensing machines

Release time:2024-07-05Publisher:Jeenoce

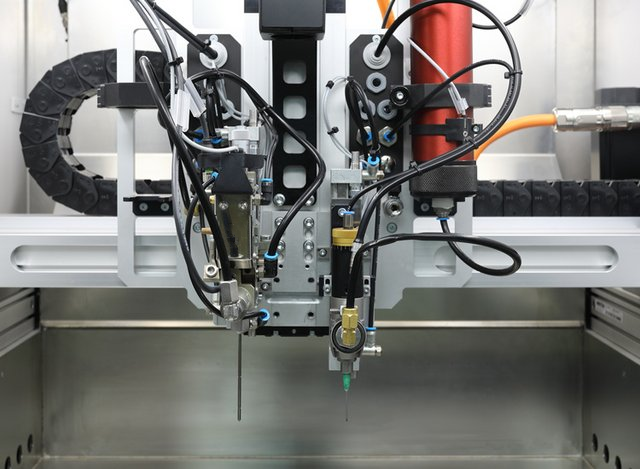

After a long period of progress, the market situation is also in a relatively stable state. Automatic dispensing machines have been used in various fields, and the required adhesive receptors are also diverse. Therefore, when using items of different shapes and sizes, automatic dispensing machines must be debugged to meet the dispensing and adhesive requirements of these items. Today, we will introduce the calibration method and precautions of automatic dispensing machines, as well as some issues that need to be noted during the process.

1. Needle selection

For items with less adhesive requirements, it is necessary to choose a suitable needle. The width and thickness of the dispensing surface vary, so it is also important to choose a needle of appropriate size. Normally, the internal structural aperture of the selected automatic dispensing machine needle should be half of the adhesive dot diameter. Of course, when the product requires a larger dispensing width but not a high thickness requirement, a needle with a straight hole can also be selected to achieve this.

2. Glue output setting

The amount of glue dispensed by an automatic dispensing machine is directly related to the actual effect of dispensing, and precision parts can affect the performance and operation of the entire component or even the entire product. The amount of glue dispensed by the dispensing machine is determined by the pressure provided by the controller to the glue tube and needle. The pressure of the dispensing machine determines the amount of glue dispensed and the dispensing speed. If the pressure is too strong or too weak, there will be imbalances and loopholes, which will affect the quality of the product. At the same time, considering the issue of dispensing efficiency, it is necessary to accurately control the dispensing time.

3. Common precautions for dispensing machines

Ensure that the dispensing machine is placed horizontally. Prevent issues such as uneven dispensing, misalignment, and glue leakage. Adjust the distance between the dispensing machine needle and the item. Prevent the occurrence of needle surface adhesion, adhesive crawling, and uneven adhesive amount during wire drawing. The dispensing time not only needs to consider efficiency and amount of glue, but also the operating environment of the automatic dispensing machine.