How to set the reflow soldering parameters for high-density components?

Release time:2024-06-25Publisher:Jeenoce

The reflow soldering parameter settings for high-density components (HDC) require special attention, as these components typically have smaller spacing and more complex thermal characteristics. JEENOCE shares the key points to consider when setting parameters for high-density component reflow soldering:

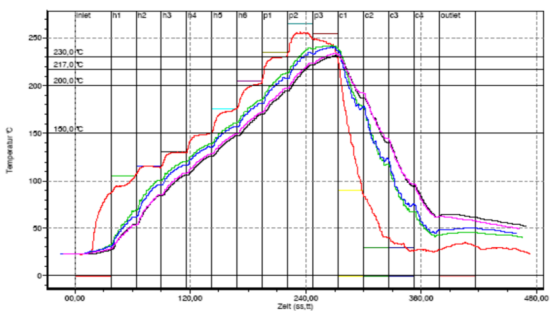

1. Preheating stage:

a、 Preheating temperature: It should be set slightly higher to ensure that the heat inside the high-density components can be evenly distributed and reduce thermal stress.

b、 Preheating time: It also needs to be increased accordingly to fully preheat the internal components and avoid local temperature differences.

2. Insulation stage:

a、 Insulation temperature: It should be ensured that the flux in the solder paste can be fully activated, while also avoiding component damage caused by excessive temperature.

b、 Insulation time: It needs to be long enough to ensure that the internal temperature of the component tends to be consistent, which helps with the subsequent welding process.

3. Reflow stage:

a、 Reflow temperature: should be higher than the melting point of the solder, but should not be too high to prevent damage to sensitive components.

b、 Reflow time: should be controlled relatively short to avoid solder loss on small pins.

4. Cooling stage:

a、 Cooling temperature: It should be cooled quickly to fix the solder joint and reduce internal stress, but the cooling speed needs to be adjusted according to specific components.

b、 Cooling method: You can choose between air cooling or water cooling, depending on the actual situation.

5. Conveyor speed:

The conveyor belt speed should be appropriately slowed down to ensure that high-density components can be fully heated in various temperature zones.

6. Furnace airflow:

Adjust the airflow inside the furnace to ensure temperature uniformity, especially during the reflux phase, to avoid local overheating.

7. Special settings:

For certain high-density components, special settings may be required, such as local heating or the use of thermal shielding to protect sensitive parts.

8. Testing and Verification:

After setting the parameters, a trial weld should be conducted and the quality of internal solder joints should be checked using tools such as X-rays and microscopes.

Due to the complexity and diversity of high-density components, specific reflow soldering parameter settings may need to be adjusted according to actual situations. It is recommended to repeatedly test and optimize the parameters based on the manufacturer's recommendations and actual welding results. In addition, for special high-density components, it may be necessary to collaborate with manufacturers to determine the optimal welding parameters.