What are the common types of dispensing valves?

Release time:2024-06-17Publisher:Jeenoce

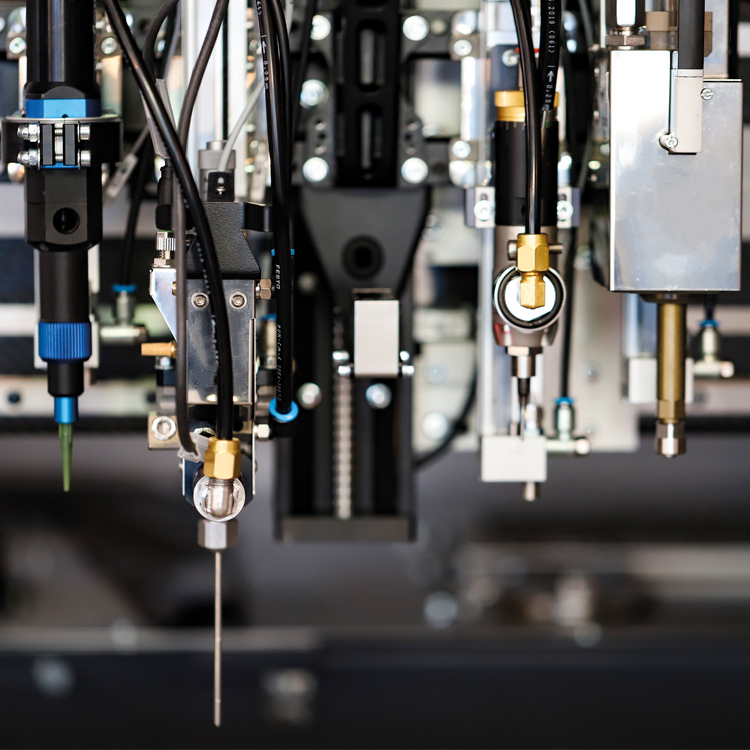

The dispensing valve is a commonly used dispensing accessory in industry, which consists of a cylinder, a valve body, and a dispensing gel. Through the interaction of the cylinder, the glue is quantitatively controlled, helping operators to more accurately control the amount and speed of glue. Due to the stronger corrosion resistance of the body of the dispensing valve through aluminum alloy anodizing treatment, it is a very effective dispensing configuration. Generally, dispensing valves are divided into pneumatic and electric types, commonly divided into the following types:

1. Spray valve

The type of spray valve is suitable for low viscosity fluids, especially when the viscosity is less than 1000 cps for spraying control, the angle can be effectively controlled by using the spray valve, and its built-in module can ensure that the fluid is atomized before spraying to prevent the fluid from blocking the valve.

2. Needle valve

Compared to other types, needle valves have stronger operability for liquids. They can control multiple single component fluids and operate high viscosity non filled fluids under high pressure. Therefore, they are often used in micro dispensing applications, and their valve needles can be replaced. Therefore, maintenance plans can be formulated based on the number of valve needle movements to ensure smooth operation of the needle valve.

3. Clamp valve

The clamp valve is equipped with a disposable wetting component, making it suitable for solvent based corrosive fluid control. Under the control of the clamp, the rubber valve can repeatedly perform medium precision adhesive operations, making it more effective for the application of two-component mixed fluids and instant drying materials. The service life of the clamp valve is short, and it should be replaced in a timely manner.

4. Volumetric valve

Volume valves are usually suitable for high-precision micro dispensing operations. Depending on the viscosity of the fluid and the amount of dispensing, spiral or pneumatic volume valves can be freely selected. Compared to spiral volume valves, pneumatic volume valves have stronger operability and lower prices.

The above are several common types of dispensing valves. In addition to the above types, there are also several types of dispensing valves such as diaphragm valves, short pipe valves, and lifting valves. In industrial dispensing applications, the selection should be based on the different characteristics of the fluid and the different dispensing requirements for spraying, dispensing points, and dispensing lines. The dispensing situation is complex and variable. Understanding the working principles and characteristics of various dispensing valves can better meet the needs of different dispensing applications.