Why is X-ray non-destructive testing so important for ensuring battery quality

Release time:2024-06-12Publisher:Jeenoce

With the popularization of battery applications such as electric vehicles and smartphones, the importance of battery quality has become increasingly prominent. X-ray non-destructive testing technology, as a non-destructive testing method, has become an indispensable part of the battery production process. So, why is X-ray non-destructive testing so important for ensuring battery quality?

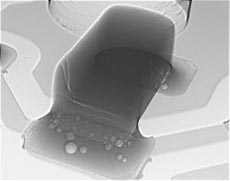

Firstly, X-ray non-destructive testing can help detect internal defects and defects in batteries. During the battery production process, due to factors such as manufacturing technology and materials, there may be defects such as bubbles, cracks, and foreign objects inside the battery. These defects may further affect the performance and lifespan of batteries, and even pose safety hazards. Through X-ray non-destructive testing, these issues can be detected early and repaired to ensure battery quality and safety.

Secondly, X-ray non-destructive testing can improve production efficiency and reduce costs. The traditional battery testing method requires dismantling the battery casing for manual inspection and testing. This method is not only time-consuming and labor-intensive, but also causes damage to the battery, increasing production costs. In contrast, X-ray non-destructive testing can perform internal testing without damaging the battery, greatly improving production efficiency and product quality, and reducing production costs.

Finally, X-ray non-destructive testing technology has high accuracy and reliability. X-ray non-destructive testing can comprehensively and accurately scan and inspect the interior of batteries, detect small defects and defects, and provide detailed testing reports. These reports can provide strong data support for manufacturers, helping them further improve production processes and product design, enhance product quality and competitiveness.

In summary, the importance of X-ray non-destructive testing technology in the battery production process is self-evident. It can help detect and repair internal defects and defects in batteries, improve production efficiency and product quality, and provide high-precision and high reliability testing reports. I believe that with the continuous development of technology and the continuous promotion of applications, X-ray non-destructive testing technology will play an increasingly important role in future battery production.