Precision quantitative dispensing valve injects new impetus into the development of manufacturing industry

Release time:2024-05-31Publisher:Jeenoce

In modern manufacturing, precise dispensing is a goal pursued by many industries, and achieving accurate control of dispensing cannot be achieved without the assistance of precision quantitative dispensing valves. Quantitative dispensing valves, as key equipment in the field of industrial bonding, have the characteristics of accurate dispensing, long service life, and fast response. They are widely used in industries such as electronics, automobiles, healthcare, and aviation, and have become the choice of manufacturing enterprises pursuing quality, efficiency, and reliability.

The key to a quantitative dispensing valve is to accurately control the amount of glue dispensed. By controlling the opening and closing time and speed of the valve core, accurate release of glue can be achieved, avoiding waste and uneven dispensing problems. Compared with traditional manual dispensing, the quantitative dispensing valve adopts programmatic control, which can achieve high-speed, efficient, and consistent dispensing effects. Its accuracy can reach 0.01mm, which can easily meet the process requirements of small sealing and high-precision dispensing.

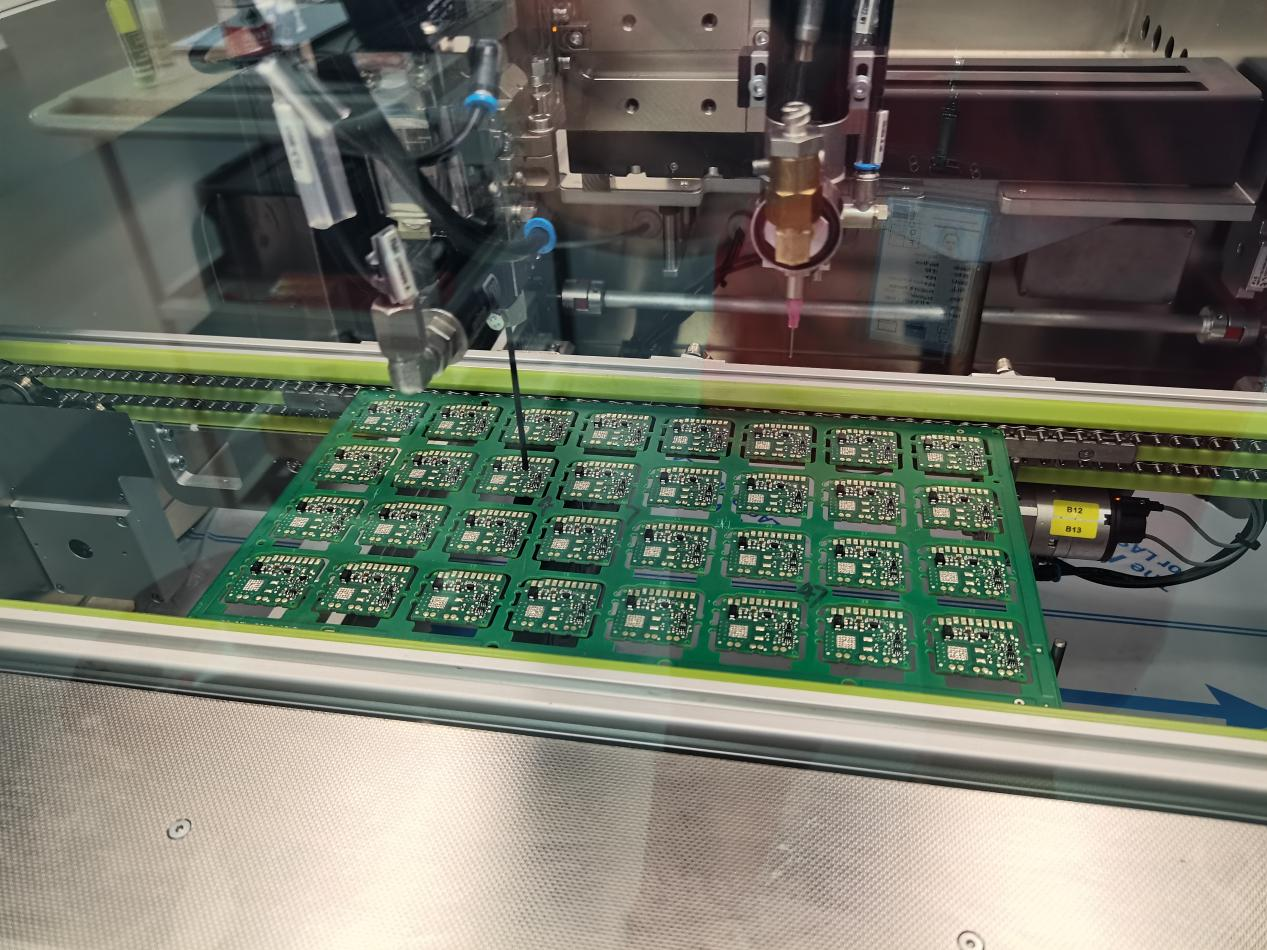

In addition, the quantitative dispensing valve also has the characteristics of automated production, which can seamlessly connect with the production line and achieve automated control. Manufacturing companies can collaborate with robots PLC and other equipment are linked to achieve requirements such as online dispensing, high-precision dispensing, and large-scale dispensing. This not only improves production efficiency, but also reduces labor costs and glue waste. Meanwhile, due to non-contact dispensing, it can also avoid problems such as collision and wear that are prone to occur in traditional dispensing, prolong the service life of the equipment, and reduce maintenance costs.

Quantitative dispensing valves are not only widely used in the electronics industry, but also play an important role in the automotive industry. In automobile manufacturing, there is a large need for dispensing of electronic components, such as car lamp components, instrument panels, controllers, etc., which requires consistent dispensing effect and reliability. For automobile manufacturers, quantitative dispensing valves can not only improve product quality, but also improve production efficiency, shorten manufacturing cycles, reduce production costs, and thus enhance competitiveness.

In summary, precision quantitative dispensing valves play a crucial role in modern manufacturing, especially in industries such as electronics, automotive, medical, and aviation. Its accurate dispensing, long lifespan, and fast response make it a choice for manufacturing enterprises to pursue quality, efficiency, and reliability. I believe that in the future, with the continuous development of technology, the application range of precision quantitative dispensing valves will be more extensive, injecting new impetus into the development of the manufacturing industry.