Why is the new energy vehicle industry inseparable from reflow soldering equipment?

Release time:2024-05-24Publisher:Jeenoce

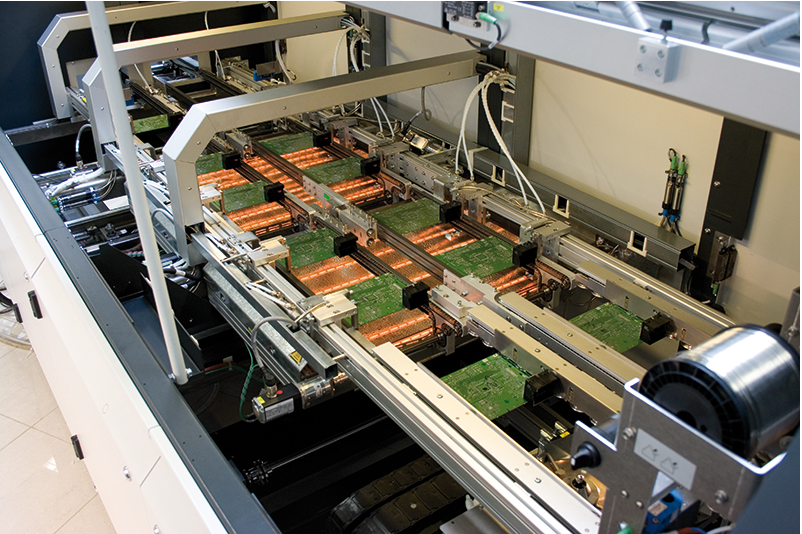

The reason why the new energy vehicle industry cannot do without reflow soldering equipment is mainly because reflow soldering technology plays a crucial role in the manufacturing process of automotive electronic components. The specific reasons can be summarized as follows:

Integration of electronic control systems: Compared to traditional fuel vehicles, new energy vehicles rely more on complex electronic control systems to manage core components such as batteries, motors, and electronic controls. These systems include a large number of circuit boards (PCBs), Printed Circuit Board), It integrates various electronic components, such as microprocessors, sensors, power management chips, etc. Reflow soldering is one of the main processes for achieving efficient and reliable soldering of these components on circuit boards, ensuring high-quality electrical connections between electronic components and PCBs.

High reliability requirements: The safety and performance of new energy vehicles are directly related to the safety of passengers, therefore there are extremely high requirements for the welding quality and long-term stability of electronic components. Reflow soldering can form high-quality solder joints in lead-free solder by precisely controlling the heating curve, improving the reliability and durability of circuit boards, and meeting the working needs of vehicles in various harsh environments.

The demand for automated production: Reflow soldering equipment supports highly automated production and can quickly and continuously process a large number of circuit boards, which is crucial for large-scale production models such as new energy vehicles. Automated production not only improves production efficiency, but also reduces the error rate of manual operations, ensuring consistency in product quality.

The trend of miniaturization and lightweighting: With the pursuit of higher energy efficiency and longer range for new energy vehicles, the miniaturization and lightweighting of electronic systems have become a development trend. Reflow soldering technology can adapt well to this demand, supporting high-density packaging technology and the soldering of small components (such as 0201, 01005 size SMT components), helping to reduce the volume and weight of circuit boards, and optimize the overall design of automobiles.

As mentioned above, reflow soldering equipment, as the core technology equipment of modern electronic assembly, is indispensable in ensuring the production of high-performance and high reliability electronic systems for new energy vehicles, and is one of the key factors driving the development of the new energy vehicle industry.