Performance of X-RAY detection in IGBT

Release time:2024-05-24Publisher:Jeenoce

Insulated gate bipolar transistor (IGBT) is a composite fully controlled voltage driven power semiconductor device composed of bipolar transistor and insulated gate field-effect transistor. It has the advantages of high input impedance of MOSFET and low on/off voltage drop of GTR.

The IGBT module has the characteristics of energy conservation, convenient installation protection, and stable heat dissipation. Most modular products sold on the market are of this type. Generally speaking, IGBT also refers to IGBT modules. IGBT is a central device for energy conversion and transmission, commonly known as power electronic equipment. As a strategic emerging industry, it has been widely used in rail transit, smart grids, aerospace, electric vehicles, and new energy equipment. With the development of energy-saving and environmental protection concepts, such products will be increasingly seen in the market.

If there are a set of three small open spaces in the solder joint connecting the IGBT chip to its heat sink, and these spaces are close to each other, it will prevent heat from quickly emitting from the area below the equipment. As time passes, the area above the gap may overheat, and the chip may experience electrical problems, leading to system malfunctions.

Due to the fact that IGBTs are commonly used for high voltage and high power applications, their malfunctions are both expensive and dangerous. It is meaningful to identify the internal structural defects of IGBT before they have a chance to develop.

From the perspective of manufacturing technology, IGBT is the same as regular semiconductor products. The industrial chain includes planning, production, packaging, and testing. Domestic enterprises have a weak process foundation in the field of IGBT and started industrialization relatively late, with insufficient accumulation in central technologies such as planning, testing, and packaging.

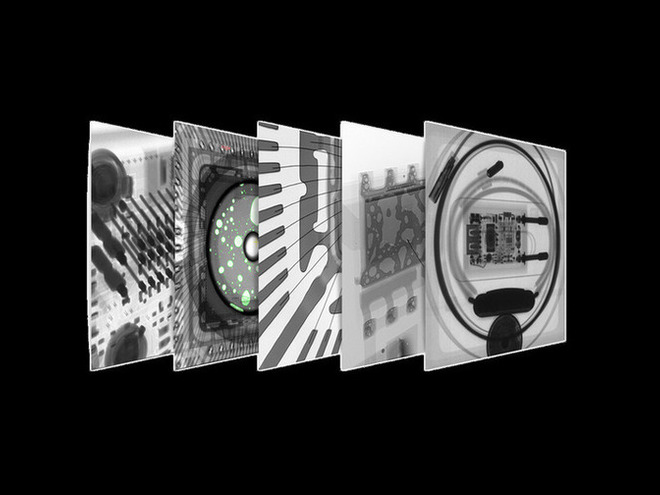

X-ray can perform non-destructive testing and imaging on IGBT, and rays can penetrate the heat dissipation fins of the IGBT module to complete useful detection. Through attenuation of the penetrating rays, local differences in the image can be observed.

X-ray detection equipment can detect IGBT modules in large quantities. IGBT is the most common type of hybrid vehicle, but it can also be used for the electric motor of traditional cars. IGBT emits a lot of heat. If any structural abnormality (such as open space or lack of adhesion) disrupts the heat dissipation pathway, it may fail due to overheating.

The biggest advantage of X-ray detection is that the detection results are intuitive, and the internal shortcomings of IGBT are displayed through images. The software's automatic recognition and judgment improve the accuracy of X-ray detection, reduce manual misjudgment rates, and ensure product quality during the IGBT production process while providing reliable improvement basis in the research and development planning stage. The X-Rav detection equipment uses the principle of X-ray transmission to detect IGBT modules, without additional cost, and the detection is fast and accurate. There are many products for X-ray testing, X-ray detection has the function of high-definition images and defect analysis, and performs extremely well in IGBT detection, making it a good choice.