Precautions for measuring reflow soldering temperature curve

Release time:2024-05-20Publisher:Jeenoce

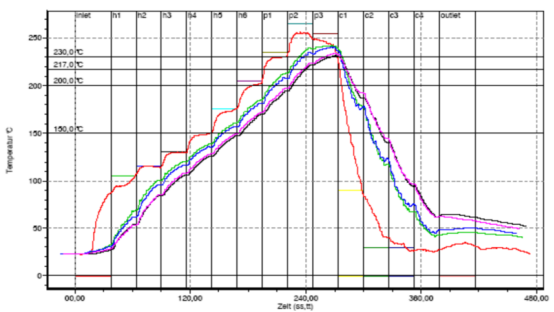

When measuring the temperature curve of reflow soldering, a temperature curve tester (hereinafter referred to as a thermometer) is required. Its main body is a flat metal box, and the end socket is connected to several micro thermocouple probes with thin wires. When measuring, solder, adhesive, and high-temperature tape can be fixed on the testing point. Turn on the switch on the thermometer, and the thermometer will enter the furnace chamber along with the tested printed circuit board. It will automatically sample and record according to the internal time program. After recording the test, connect the tester to the printer to print multiple temperature curves of various colors. Thermometers, as the eyes and tools of SMT technicians, have been widely used in the external SMT industry.

When using a thermometer to measure the reflow soldering temperature curve, the following points should be noted:

1、 When measuring the reflow soldering temperature curve, a fully assembled plate must be used. Analyze the thermal characteristics of printed circuit board components. Due to differences in the heating performance of printed circuit boards, differences in component volume and materials, the actual heating rise at each point varies. Identify hot and cold points, and set thermocouples separately to measure high and low temperatures.

2、 Set up as many thermocouple test points as possible to comprehensively reflect the actual heating status of various parts of the printed circuit board. For example, the degree of heating on the center and edge of a printed circuit board is different, the thermal capacity of large and small components is different, and testing points must be set for thermal sensitive components.

3、 The appearance of the thermocouple probe is small and must be fixed in the testing position with designated high-temperature solder or adhesive, otherwise it will loosen due to heating, deviate from the predetermined testing point, and cause testing errors.

4、 The batteries used are two types: lithium batteries and rechargeable nickel cadmium batteries. Reasonably test and charge in a timely manner based on specific circumstances to ensure the accuracy of test data.