The principle of X-ray inspection in PCB assembly

Release time:2024-05-17Publisher:Jeenoce

X-ray detection technology, commonly known as Automatic X-ray Inspection (AXI), is a technique used to examine hidden features of target objects or products using X-rays as a source. Nowadays, X-ray testing is widely used in many fields such as healthcare, industrial control, and aerospace. As for PCB inspection, X-rays are widely used in the PCB assembly process to test the quality of PCBs, which is one of the most important steps for quality oriented PCB manufacturers.

Technological development drives X-ray forward

In recent years, surface array packaging, including BGA and QFN, flip chip, and CSP, has been widely used in various fields such as industrial control, communication, military, aviation, etc., causing solder joints to be hidden under the packaging. This fact makes traditional detection equipment unable to play its perfect role in PCB detection. In addition, due to the appearance of surface mount technology (SMT), both packaging and leads become smaller, traditional detection methods (including optics, ultrasound, and thermal imaging) are insufficient because PCBs have higher density, hidden solder joints, loopholes, or blind holes. In addition, with the increasing miniaturization of semiconductor component packaging, while considering X-ray detection systems, the current and future trend of component miniaturization cannot be ignored. Compared with other detection methods, X-ray can penetrate into the inner packaging and inspect the quality of solder joints. That's why it was picked up.

Principles of X-ray Inspection

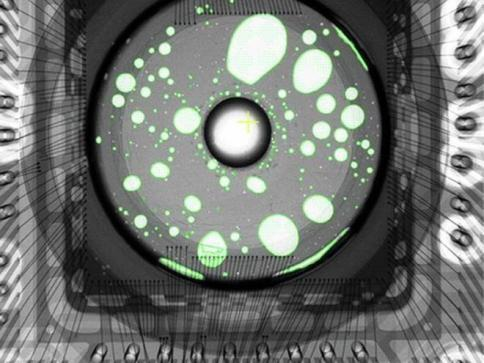

The unique advantage of X-rays is that they absorb X-rays directly proportional to their atomic weight, and all materials absorb X-ray radiation according to their density, atomic number, and thickness. Generally speaking, materials made from heavier elements absorb more X-rays and are easier to image, while materials made from lighter elements are more transparent to X-rays.

Dark black images refer to materials composed of heavy elements, while transparent or relatively white images refer to materials composed of light elements. Therefore, X-ray examination can effectively detect hidden defects, including open circuits, short circuits, misalignment, and missing electrical components.

X-ray testing technology has brought new changes to production testing methods. It can be said that it is a sensitive choice for manufacturers who are eager to further improve production process level, improve production quality, and timely detect electronic assembly faults as a breakthrough point. With the future development trend, other assembly fault detection methods are difficult to move forward due to their limitations. X-ray detection equipment will become a new focus of production equipment in the future and play an increasingly important role in the production field!