How to solve the problem of uneven solder paste dispensing and wire drawing?

Release time:2024-05-17Publisher:Jeenoce

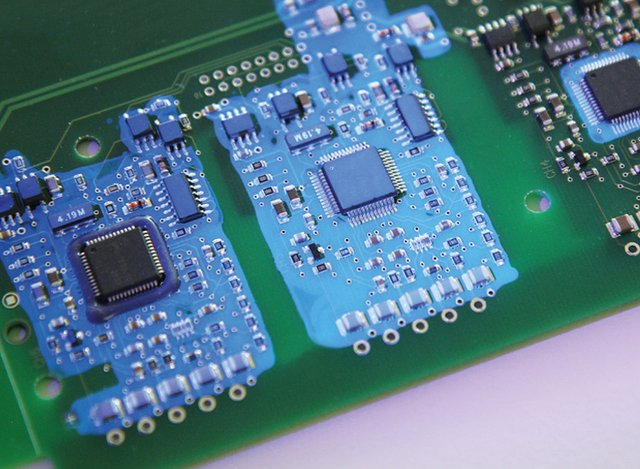

Because it is rare in practical life, many people are not particularly familiar with the solder paste dispensing process. However, this process plays a very important role in the manufacturing industry and is widely used in the automotive, mobile phone parts manufacturing, and semiconductor industries. Although the production process of solder paste dispensing is relatively fine, uneven wire drawing occurs during operation, so it needs to be resolved in a timely manner.

Before learning to solve the problem of solder paste dispensing, it is necessary to first understand this process. This process is also known as needle tube solder paste, which involves filling the solder paste glue into the needle tube and dispensing it through the contact of the needle with the solder plate. Needle tube solder paste can optimize the dispensing process, thereby painting patterns of points, lines, and patterns.

A common problem during the dispensing process is uneven drawing, and the following measures can be taken:

1. Delayed glue opening. There is a distance between the glue outlet and the glue room. If a delay in glue opening is not set, it may result in a section where the glue cannot be applied, which may be intermittent during dispensing.

2. Delayed glue closing. After closing the glue, there may still be a small amount of glue that has not fully flowed out. If the glue is turned off at this time, it may cause glue or blockage. The next time it is used, it will lead to uneven adhesive release, resulting in uneven wire drawing.

3. Adjust the drawing height. Compared to regular glue, solder paste glue has a higher viscosity. When dispensing, it is necessary to adjust the height of the wire drawing appropriately so that the wire can be pulled off in a timely manner after dispensing.

4. Adjust the lifting height. In order to prevent uneven drawing caused by the dispensing needle hitting the needle, the height of the upper stage can be adjusted appropriately before dispensing.

5. Reserve completion trajectory. After dispensing, there may be glue stacking, so it is necessary to reserve some space to ensure timely removal of the dispensing machine.

6. Slant up and lift. As mentioned earlier, the viscosity of solder paste adhesive is relatively high, and a simple and rough drawing action after closing the adhesive cannot completely break the adhesive wire. Therefore, after closing the adhesive, the adhesive wire should be pulled in a timely manner by pulling it diagonally onto the platform.