Semiconductor testing is becoming increasingly important, how to conduct semiconductor testing?

Release time:2024-05-10Publisher:Jeenoce

In recent years, with the development of new generation information technologies such as artificial intelligence, big data, and the Internet of Things, the global semiconductor industry has ushered in another round of prosperity cycle. In order to solve the contradiction between demand and supply mismatch, China is vigorously developing the semiconductor industry in order to achieve domestic substitution. Since the implementation of the large fund in 2014, the entire semiconductor industry chain in China has experienced rapid development and will continue to strengthen its position in the semiconductor industry in the future.

With the development of technology, the density of semiconductor chip transistors is increasing, and the complexity and integration of related products are showing exponential growth, which is an unprecedented challenge for chip design and development. On the other hand, with the shortening of chip development cycles, there is a high demand for the success rate of chip fabrication, and any failure is unbearable for enterprises. Therefore, sufficient verification and testing are required during the chip design and development process. In addition, the continuous improvement of semiconductor process technology requires a large number of technical challenges, and testing and verification have become more important.

How to conduct semiconductor testing?

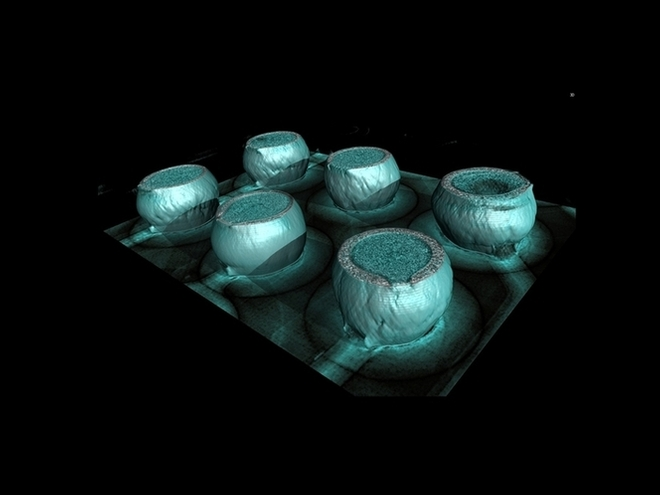

Semiconductor testing mainly involves detecting the front-end and back-end processes of semiconductors. The packaging processing technology includes: slicing, loading, bonding, plastic sealing, trimming, electroplating, printing, cutting ribs, and visual inspection of the formed part.

Before inspection, check if there are any defects on the surface of the wafer that affect the yield to ensure that the yield of the processing line is controlled above the specified level. Post processing detection is mainly used in the wafer processing and IC packaging process, which is an electrical and functional detection used to check whether the chip meets performance requirements.

Both front-end and back-end semiconductor testing require a device, X-ray real-time online imaging equipment, which accurately detects defects and improves yield through the imaging principle of X-ray.