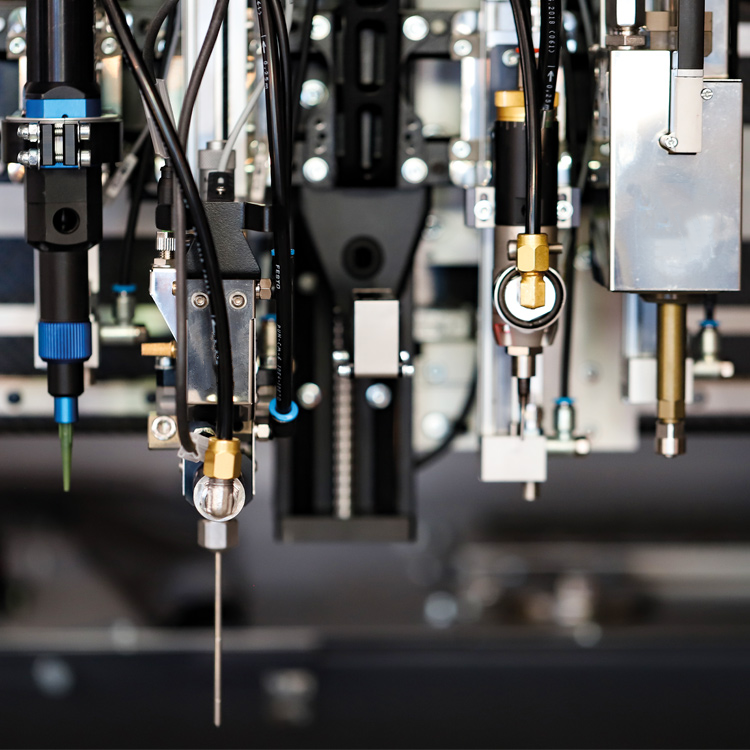

Chip packaging semiconductor dispensing

Release time:2024-05-10Publisher:Jeenoce

With the continuous advancement of technology, more and more electronic devices require the use of small and complex chips to achieve functions. Among them, chip packaging is a crucial step in encapsulating these tiny chips in protective shells. In this process, semiconductor dispensing equipment plays an important role. In addition, the characteristics of intelligence also enable devices to conduct real-time monitoring and data analysis, providing valuable feedback information for the production process, helping to optimize production processes and product quality.

1. High precision dispensing

Semiconductor dispensing equipment for chip packaging has the ability to provide high-precision dispensing. During the chip packaging process, water needs to be applied to the chip and other components in a very accurate manner. Semiconductor dispensing equipment, through precise control systems and advanced nozzle design, can achieve accurate dispensing at the micrometer level, ensuring that the glue is evenly distributed in the correct position, thereby providing reliable bonding effects.

2. Multifunctional applications

Semiconductor dispensing equipment for chip packaging also has the advantage of multifunctional applications. Different chip packaging processes may require the use of different types of adhesives and dispensing on different surfaces. Semiconductor dispensing equipment can be adjusted according to specific needs to adapt to different types of glue and dispensing tasks. They have multiple nozzles and spray modes, allowing for flexible switching from fine dispensing to large-area dispensing. This multifunctional application capability makes semiconductor dispensing equipment an ideal choice for various chip packaging processes, improving production efficiency and flexibility.

3. Automation and Intelligence

With the development of the semiconductor industry, the application of automation and intelligent technology in the production process is becoming increasingly common. The semiconductor dispensing equipment for chip packaging has the characteristics of automation and intelligence, bringing huge advantages to the production line. By integrating advanced sensors, control systems, and machine vision technology, semiconductor dispensing equipment can achieve automatic detection, calibration, and control, improving the efficiency and stability of the production line.

The high-precision dispensing ability and intelligent characteristics of semiconductor dispensing equipment for chip packaging enable it to reduce glue waste and improve the throughput of production lines. In addition, semiconductor dispensing equipment can also reduce production costs by reducing manual operations and improving production efficiency.