Working principle of high-performance and environmentally friendly lead-free reflow soldering equipment

Release time:2024-05-07Publisher:Jeenoce

High temperature drying tunnel furnace is an indispensable part of high-performance and environmentally friendly lead-free reflow soldering equipment. Its working principle is to dry the assembled components on the circuit board using high-temperature hot air to ensure welding quality and stability. This article will provide a detailed introduction to the working principle of a high-temperature drying tunnel furnace and explore its importance in lead-free reflow soldering equipment.

In modern electronic manufacturing industry, reflow soldering is a common method of connecting components assembled on circuit boards. Lead free reflow soldering is of great significance in reducing environmental pollution. However, lead-free solder requires higher temperatures during the welding process, which requires the assistance of a high-temperature drying tunnel furnace.

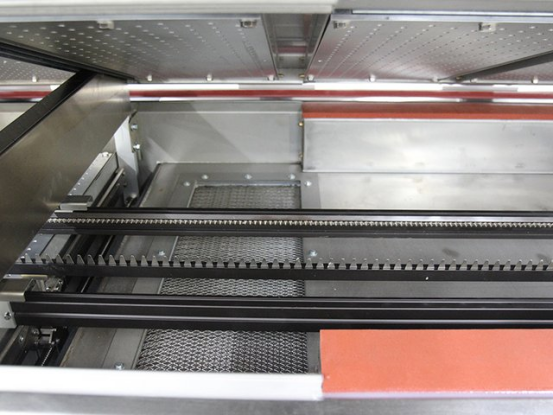

The working principle of a high-temperature drying tunnel furnace mainly includes the following steps: first, the circuit board enters the furnace through a conveyor belt; Then, the heating elements inside the furnace generate high-temperature hot air; Next, the high-temperature hot air evenly blows the assembled components on the circuit board through the channels inside the furnace; Finally, the high-temperature hot air evaporates the moisture on the assembled components, achieving the purpose of drying.

The design and operation of high-temperature drying tunnel furnaces need to balance performance and environmental requirements. Firstly, the channel design inside the furnace should ensure that high-temperature hot air can evenly blow on the circuit board to ensure that each assembled component can be properly dried. Secondly, the heating elements inside the furnace should have the characteristics of high temperature and rapid response, so as to quickly reach the required drying temperature. In addition, in order to protect the environment, smoke exhaust devices need to be installed inside the furnace to effectively remove the waste gas and harmful substances generated inside the furnace.

The high-temperature drying tunnel furnace plays a crucial role in lead-free reflow soldering equipment. By high-temperature drying, the moisture during the welding process is removed, avoiding the problem of residual moisture on the circuit board after welding, which leads to unstable solder joints. In addition, high-temperature drying also helps to improve the flowability and wettability of lead-free solder, thereby improving welding quality and reliability.

In summary, the high-temperature drying tunnel furnace is an indispensable part of high-performance and environmentally friendly lead-free reflow soldering equipment. It dries the assembled components on the circuit board through the action of high-temperature hot air, ensuring welding quality and stability. In the lead-free reflow soldering process, the high-temperature drying tunnel furnace plays an irreplaceable role.