Why are vacuum glue machines more expensive than general glue machines

Release time:2024-05-07Publisher:Jeenoce

In other words, a vacuum glue machine is a type of machine equipment that works under a vacuum. Because it operates in a negative pressure natural environment, the technical standards for the machine equipment are higher. Due to the fact that a typical cup of water can freeze under negative pressure standards in a natural environment of 0.2Mpa, the extreme level inside the vacuum can be seen. Therefore, placing glue in a vacuum makes the processing process more complicated, and the technical requirements for the equipment and spare parts materials are higher. The actual technical requirements are reflected in the control glue and AB glue preparation level. Let's first gradually interpret from the AB glue preparation level, because the negative pressure increases in the negative pressure natural environment, and the relative density of the glue will also occur. Changes can harm the fluidity of glue. In the measurement and verification of glue, if there is an error in the measurement and verification of glue, it can cause the glue to not dry or partially dry and solidify, Causing complete product damage, the same applies to the adhesive control layer. Under negative pressure working pressure standards, it is necessary to ensure consistent adhesive force to prevent intermittent dripping. Excessive or insufficient adhesive can also cause product damage. Therefore, at the level of equipment technology and system configuration regulations for vacuum betting glue, the technical shortcomings increase the R&D cost of product development and design, and the strict regulations on system configuration result in an increase in mandatory cost fees. This is why the use value of vacuum gluing machines is higher than that of general gluing machines.

What are the advantages

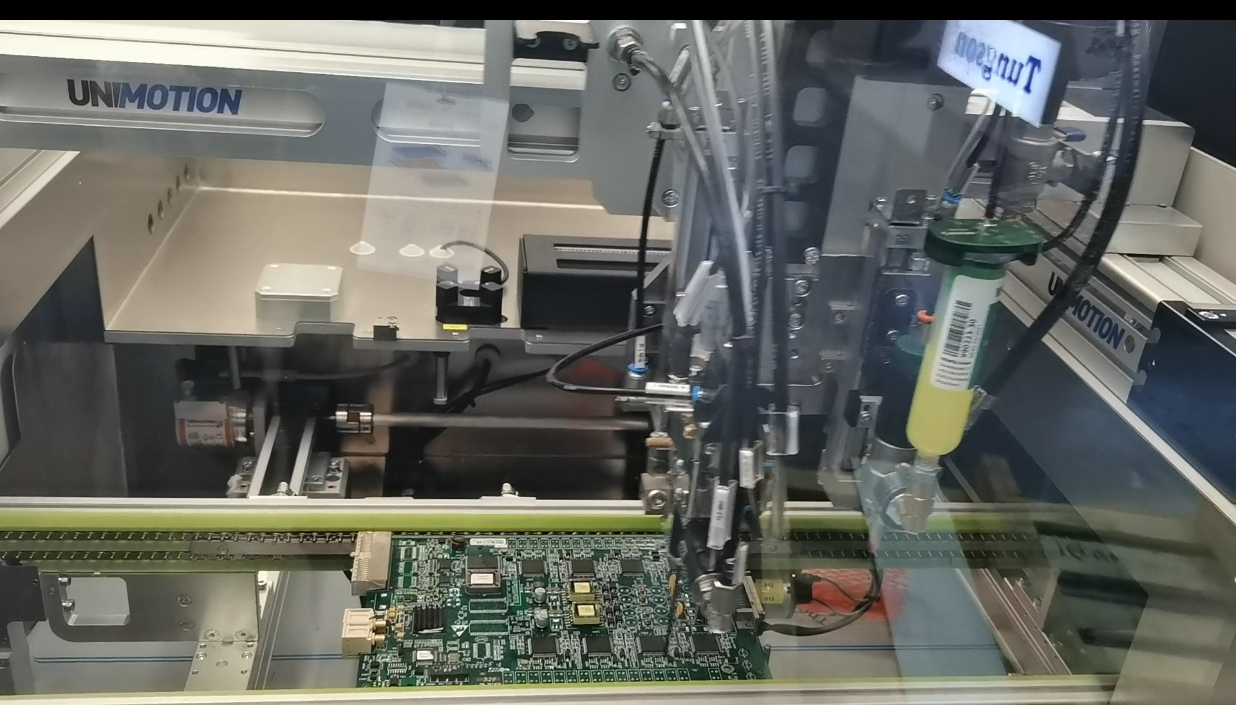

Principle: Place the product in a vacuum pump, mix the two components according to a certain formula, and then proceed with gluing. The goal is to greatly improve the quality of glue filling, with a high level of automation technology, reduce process flow, and increase productivity. It can be used for two liquid composite resins such as dual liquid epoxy resin adhesive, dual component polyurethane material, and dual component silicone. It is suitable for products with complex structure and fortress quality regulations for injection molding.

The widespread application in the electronic industry is also increasing, especially in the packaging of the electronic device industry chain, such as transformers, automotive relays, switching power supplies, motor electromagnetic coils, and other products, which are used for vacuum sealing work. This is also something that ordinary glue machines cannot replace. Simply put, in fact, a vacuum gluing machine is based on a general gluing machine, which extracts all the gas in the material tank and maintains the vacuum pump condition continuously. Subsequently, the natural environment for product gluing also maintains the vacuum pump condition, which can avoid the entire process caused by bubbles. Little did they know that its application is basically not affected by the external natural environment, so the characteristics of the machine equipment are stable, high-precision glue filling, and reliable operation.

And precisely because of this characteristic, compared to injecting under superheated steam, the adhesive sticking too high is difficult to remove bubbles, and the adhesive with bubbles inside the product is not easy to penetrate, resulting in uneven and uneven surface of the poured product, with vastly different characteristics. At this point, the effectiveness of the vacuum grouting machine can be reflected. The vacuum grouting machine is a working method that maintains 3-4 injections of the product under high-quality negative pressure conditions. By using the interaction force of negative pressure, the gas from the vacuum chamber body is first sucked out during the entire injection process, and then the product injection is carried out. It can quickly penetrate the adhesive into the interior of the product, and the impact of injection and the bubbles caused by the contact between the adhesive and the product can also be quickly sucked out under the negative pressure effect, thereby ensuring excellent performance of the product.