Advantages of X-RAY Detection for IGBT Semiconductor Packaging Modules

Release time:2024-04-11Publisher:Jeenoce

In the process of IGBT semiconductor packaging module operation, there are relatively complex technical processes. However, how to carry out quality identification and testing of packaging has become the most helpless process for enterprises. In the increasingly fierce market competition, the continuous improvement of product quality standards, and cost control, greater efforts are needed. This is also a difficult problem that the current IGBT semiconductor packaging industry urgently needs to solve.

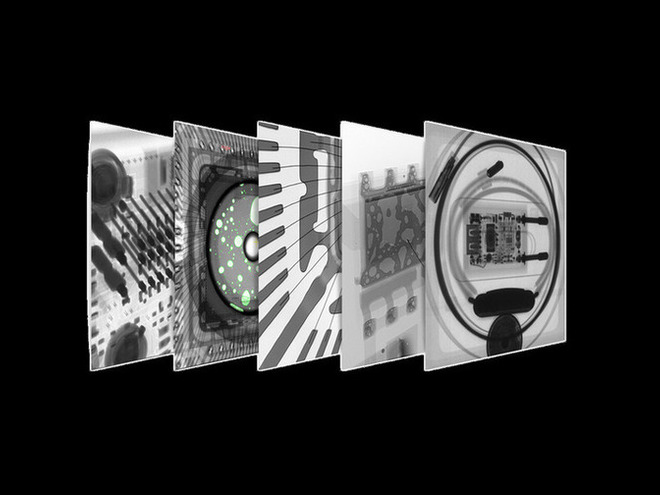

X-ray detection technology adopts a penetration operation method, without the need to disassemble the product, similar to medical X-ray chest X-ray and other tests, but the intensity of X-ray industrial testing is higher. At present, X-ray detection equipment is widely used in PCBA circuit boards, IC chips, IGBT semiconductors, lithium batteries, LED beads and other fields.

The IGBT module is tested using the principle of X-ray transmission, which is fast and accurate. When the X-Ray detection equipment passes through the IGBT module, it can directly observe whether there are any defects such as bubbles inside the IGBT module, and the location of the defects can also be directly observed.