How to distinguish between a three-axis dispensing machine and a four-axis dispensing machine?

Release time:2024-04-03Publisher:Jeenoce

What is the difference between a three-axis dispensing machine and a four-axis dispensing machine? I believe many people are not very clear about this issue, but in fact, their differences are not very big. The most commonly used ones are the XYZ axis, which is the XYZ axis. Why are the three axes commonly used? Because usually, a low request for three axes is enough to meet our needs! Today, JEENOCE will explain to you the differences and characteristics between three-axis and four-axis systems.

Features of three-axis dispensing machine:

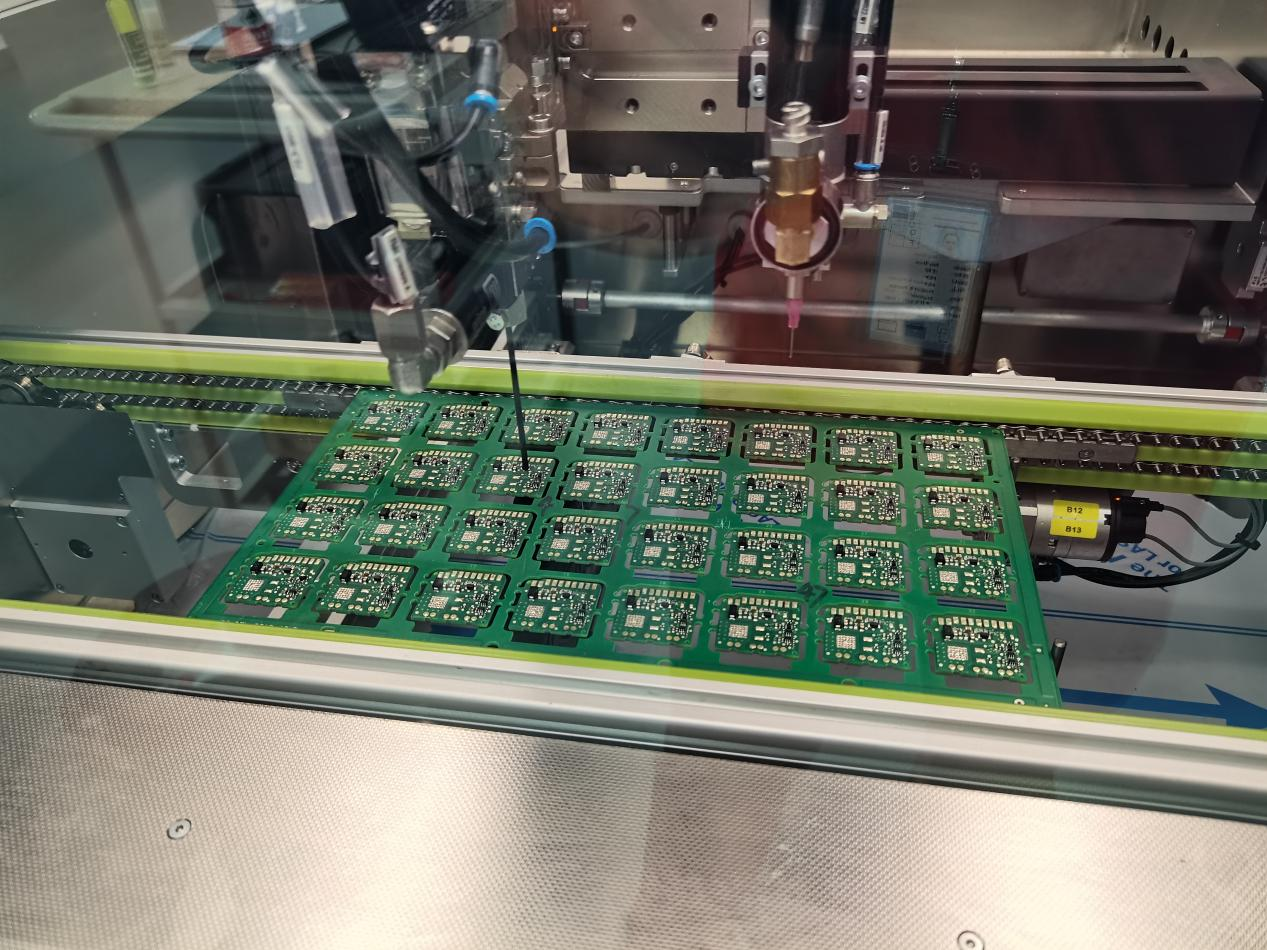

Three axis glue dispenser, also known as automatic glue dispenser, is widely loved by major manufacturers and is one of the most popular types in the market today! Commonly used in the packaging of the electronics industry, in recent years, the dispensing machine has been constantly improved, making it an essential consumer equipment in the dispensing process for enterprise consumption! Can replace manual dispensing operations and complete mechanical automation consumption; The map function that is suitable for convenient use; Smooth corner treatment; The high-strength equipment body adopts CNC integrated processing, effectively ensuring the verticality of XYZ and improving the machining accuracy of the equipment.

Compared to the three axis dispensing machine, the four axis dispensing machine is a bit more advanced: it has graphics elements such as drawing points, straight lines, multi segment lines, three-dimensional arcs (spatial arcs), circles, ellipses, runways, distance shapes, spiral lines, coating, automatic rounding, irregular three-dimensional spline curves, etc., and can complete 360 degree rotation dispensing completely.

Features of the four axis dispensing machine:

1. Single machine operation, convenient installation, and simple operation.

2. After stopping programming with a handheld programmer, precise positioning and glue dispensing control are used to achieve multi axis linkage, completing spatial linear interpolation or two axis circular arc interpolation;

3. The compact construction design makes the equipment more durable and adheres to the accuracy of dispensing.

4. It can store multiple independent running programs, so that when used again, it can be quickly called without the need for reprogramming.

5. The dispensing machine has the function of avoiding local stacking and accumulation of glue in sharp bends, making the gluing area more perfect.

6. This automatic glue dispensing machine has independent universal input and output contacts, which can complete satisfactory glue coating, dispensing, and spraying requests;

7. Online teaching function for dispensing glue and exercise forms; It can easily complete various powerful functions such as matrix copying, offset correction, calibration point setting, and program transmission between various machines.

8. Simple programming methods are easy to learn and use, and can be applied without professional training. Learning to operate and maintain is simple and fast