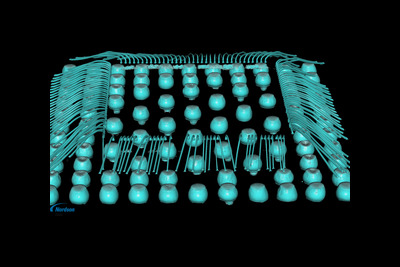

X-RAY equipment detects whether there is empty welding or false welding in BGA

Release time:2024-04-02Publisher:Jeenoce

Generally speaking, workers in factory workshops are more or less exposed to SMT, and it seems difficult to quickly distinguish whether there is insufficient solder, bubbles, or short circuits in PCBA soldering. Traditional visual inspection or AOI testing cannot effectively determine whether there is empty solder in BGA. With the development of industry, more and more enterprises keep up with the times and use X-RAY perspective to detect defects in the internal structure of products.

BGA solder balls become larger, causing empty soldering

The current industrialized dispensing soldering technology is very effective in controlling the amount of tin. If the amount of tin is almost the same, the size of the solder balls must be similar. However, if the solder balls contain bubbles and voids, the size of the solder balls will be completely different. Before reflow soldering, two solder balls are the same size. After reflow soldering, there is a significant change in the diameter of one solder ball, which is mostly caused by empty soldering.

Insufficient tin content caused by tin eating through the conductive hole

Due to issues with the PCB board material or solder pad process design, some of the tin after soldering is absorbed by the material, resulting in insufficient amount. This can easily cause the diameter of the solder ball to decrease. If the amount of tin is absorbed too much, it can easily lead to empty soldering.

There are bubbles inside the tin ball

The appearance of bubbles inside the solder ball cannot be seen from the appearance, and some evidence may be obtained due to changes in diameter. However, different amounts of solder can cause changes in the diameter of the solder ball. Generally, X-RAY detection equipment is used for direct penetration detection of bubbles. The size of bubbles inside the solder ball is strictly required by the industry. Please refer to the "Technical Requirements for PCB Solder Bubble Area" for details.