What is the difference between CT equipment and X-RAY 2D detection equipment?

Release time:2024-04-01Publisher:Jeenoce

At present, most non-destructive testing equipment on the market is mainly based on two-dimensional image detection. However, for complex product structures, a single angle may obscure defects. Therefore, during testing, it is necessary to rotate the object to be tested in multiple dimensions, which is very laborious to operate. If inexperienced operators are encountered, they may even be unable to understand the image.

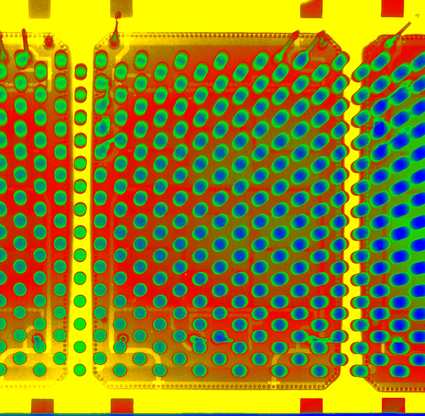

The emergence of CT adopts a 360 degree detection method to deeply analyze images from details, including motion accuracy and rotation accuracy. The scanned images of each face are synthesized into 3D models. Of course, the components used are also more high-end, and the images obtained from each angle are at the u level, which better ensures that the 3D synthesis is more intuitive and accurate.

What is the difference between CT equipment and X-RAY 2D equipment?

Price: CT uses more high-end components, with more obvious technological advantages and higher costs;

Function: Undoubtedly, CT is more advanced in terms of functionality. It can synthesize 3D models on the basis of 2D to intuitively display product characteristics;

The above intuitively explains the difference between CT and 2D. It is obvious that CT is more worth having, but in terms of market demand, not every product inspection requires CT, after all, its expensive price and cost are there. For common market demands such as looking for bubble defects, product cracks, etc., using X-RAY 2D can perfectly solve these problems.

For enterprises to detect internal defects in their products, X-RAY 2D can be used instead of expensive CT purchases. CT equipment is more suitable for the electronics industry if there is a need for copying (i.e. purchasing chips and hoping to learn and imitate them through technical analysis), otherwise X-RAY 2D is sufficient to meet customer needs.