Working principle of electric dispensing valve

Release time:2024-04-01Publisher:Jeenoce

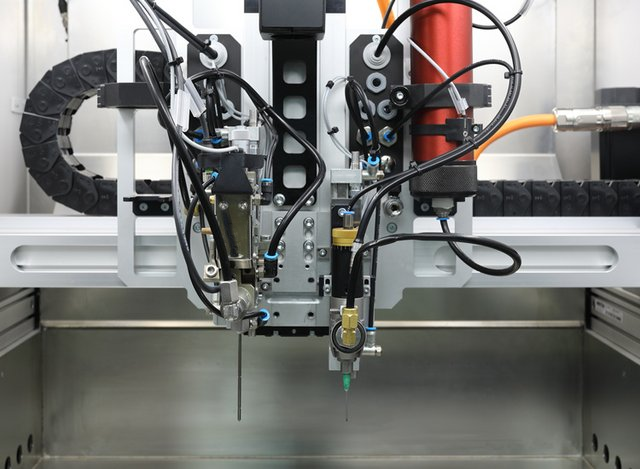

Working principle: Adopting a single screw structure and utilizing the principle of single screw volumetric conveying, the rotor and stator form a self sealing structure. The directional rotation of the rotor in the stator cavity realizes the medium conveying function. The transportation process does not have any impact on the performance of the medium. At the same time, the dispensing machine can easily achieve the function of medium suction by reversing the motor, ensuring the cleanliness of the medium and materials, no dripping, and no pollution! Glue is loaded into a pressure bucket, compressed air enters the pressure bucket or storage bucket, and the glue is pressed into the feed pipe connected to the material cylinder chamber; Give a signal to the solenoid valve to drive the dispensing valve piston to move downwards, and the glue will pass through the material cylinder and be pressed out from the needle.

Electric: including pump body and driving part, equipped with stator, easy to install. The dispensing machine adopts a fixed rotor structure design, with good sealing performance. The rotor and stator pair form a self sealing structure, which is easy to replace. Through the directional rotation of the rotor in the stator cavity, the medium conveying function is achieved.

Top needle dispensing valve: It moves in the opposite direction to the suction dispensing valve and sends a signal to the solenoid valve, which drives the dispensing valve piston to move upwards. The glue passes through the material cylinder and is pressed out from the needle. The amount of glue that drips out is determined by three factors: the control solenoid valve time, the pressure of the pressure bucket, and the piston movement stroke, that is, the fine adjustment of the dispensing valve. This allows it to be freely matched with any automation equipment.

Whether to enter the dispensing pump through the rubber hose can be replaced by following the steps below:

1) Check the adapter for the connecting hose and dispensing valve. The dispensing machine mainly checks for any overflow of colloids, and if so, wipe them off.

2) Then close the dispensing machine door.

3) Finally, restart the dispensing machine equipment.

4) Then reinstall the air pressure head.

5) Then reinstall the cooling sleeve of the rubber hose.