Control methods for reflow soldering process

Release time:2024-03-28Publisher:Jeenoce

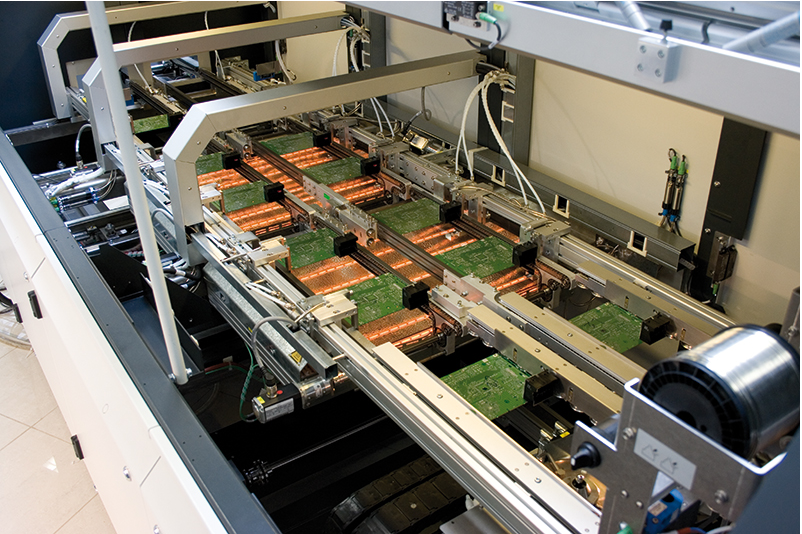

Reflow soldering technology is actually not as simple as many people think. Especially when you require zero defects and guaranteed welding reliability (lifespan). Based on summarizing the experience and sharing of customer reflow soldering process control methods in large-scale SMT production and processing, JEENOCE will provide a comprehensive overview.

1、 To ensure a good reflow soldering process, the following practices should be followed when reflow soldering is not performed:

1. Understand the quality and welding requirements on your PCBA, such as high temperature requirements and solder joints and components that need to be taken care of in terms of lifespan;

2. Understand the welding difficulties on PCBA, such as the parts with solder paste printing larger than the solder pad, the parts with extremely small spacing, etc;

3. Identify the hot and cold points on the PCBA, and weld temperature measurement and thermal coupling on the points;

4. Determine other necessary locations for thermal coupling temperature measurement, such as BGA packaging and bottom solder joints, thermal sensing device body, etc. (try to use all temperature measurement channels to obtain more information);

5. Set initial parameters and compare them with process specifications (Note 9) and adjust them;

6. Carefully observe the welded PCBA under a microscope, observing the shape and surface condition of the solder joints, degree of wetting, direction of tin flow, residues, and solder balls on the PCBA, etc. Especially pay more attention to the welding difficulties recorded in point 2 above. Generally speaking, after the above adjustments, there will be no welding faults. But if there is a malfunction, analyze the fault mode and adjust it in conjunction with upper and lower temperature zone control based on its mechanism. If there are no faults, determine whether to perform fine-tuning optimization based on the obtained curve and the solder joint situation on the board. The purpose is to ensure the stability and low risk of the set process. When adjusting, consider the furnace load and production line speed issues to achieve a better balance between quality and output.

The setting and adjustment of the above process curves must be carried out using actual products to have confidence. The cost of using actual product test boards may be an issue. Some users assemble boards that are very expensive, which is why they are unwilling to frequently test the temperature. Users should evaluate the debugging cost and the cost of encountering problems. In addition, the cost of test boards can also be improved and saved by using methods such as fake parts, scrap boards, and selective SMT.

2、 Reflow soldering process control:

The six steps we discussed above are process setup and modulation. Once we are satisfied with its effectiveness, we can proceed to mass production. From this moment on, process control becomes very important. Once the welding parameters (temperature, time, air volume, wind speed, load factor, exhaust, etc.) are determined, ensuring the stability of these parameters is the goal of process monitoring.

At present, it is not ideal that many users have not conducted any monitoring of the above process parameters. Those who do slightly better may authenticate the temperature curve during a fixed time period. The method is to use a test board and temperature measuring instruments to measure in the furnace and compare them with the original records. Nevertheless, there are still some drawbacks to this approach. The frequency and time of measurement lack scientific formulation, with more emphasis on intuitive decision-making. The second reason is the low reliability of sampling. If this approach is to ensure high efficiency, it must be based on in-depth research and performance certification of the equipment.

For industries with high quality requirements, such as automotive electronics, military products, medical equipment, supercomputers, power protection, etc., the above sampling control is not sufficient. There is currently a real-time monitoring system on the market that can continuously monitor the airflow and temperature inside the furnace. The process control objectives achieved. The only drawback is that the design has not yet been fully integrated into the temperature control system of the furnace, so it still belongs to a monitoring system rather than a control system. However, this system has already brought benefits to users in the field of process control. It is understood that this type of technology is currently widely used in Europe and America, and Japanese and Korean companies have also begun to adopt it in the past two years. Taiwanese companies have also been using it more in recent years due to the influence of the United States. However, only Chinese enterprises use it very little. This is related to the procurement concept (Note 10) and the understanding of technology application and management. But I think it's just a process of understanding and learning. I believe that in the future, Chinese enterprises will also extensively use this process control technology. I have communicated with some SMT users about this system before, but many of them are not familiar with this technology and often mistake it for repeating the temperature control function inside the furnace. In fact, the internal control system of the furnace usually only monitors the temperature without monitoring the airflow, and there is also a certain delay in the furnace's return temperature reaction, which is not preventive. That is to say, with current furnace control technology, the furnace itself cannot guarantee that there will be no errors. And this real-time monitoring system, although currently unable to prevent the occurrence of quality problems, has the ability to tell users the fault information that the furnace cannot provide. In addition to this, the system also has the function of risk prediction and QA. It is a tool worth considering.

3、 Requirements for reflow soldering equipment:

A good reflow soldering furnace is an important part of ensuring good craftsmanship. Especially for enterprises engaged in processing services (CM or EMS industries), due to the lack of control over design, the ability to compensate and adjust processes becomes the key to success. This not only requires mastery of process knowledge similar to that in this article, but also places a greater reliance on equipment performance. What is considered a good reflow soldering equipment? We can evaluate based on the following characteristics.

1. Heating efficiency; 2. Thermal stability (including temperature, wind speed, and air volume); 3. Heat capacity; 4. Heating speed; 5. Air flow permeability; 6. Air flow coverage and uniformity; 7. The adjustability and controllability of wind speed and air volume; 8. The degree of interval between temperature zones; 9. The number of temperature zones; 10. The length of the heating zone; 11. The controllability of cooling; 12. Requirements for exhaust

It is not difficult to see from the above characteristics that characteristics beyond half are not included in the technical specifications of the equipment. And that's why choosing a welding furnace is not guaranteed from paper discussions and evaluations. The only way is to test the physical object.

Finally, JEENOCE emphasizes the concept of reflow soldering process control. Any process, if it is to be done well, must consider technological integration. This integration includes design (DFM), equipment, process, and materials., This also includes the integration of technology (how to weld, etc.), practices (quality control methods, etc.), and management (how to establish effective processes and knowledge teams, etc.). Similar to processes such as solder paste printing or SMT, reflow soldering is also a system that is not as simple as many of us imagine.