The significance of X-ray layering method in detecting BGA welding points

Release time:2024-03-28Publisher:Jeenoce

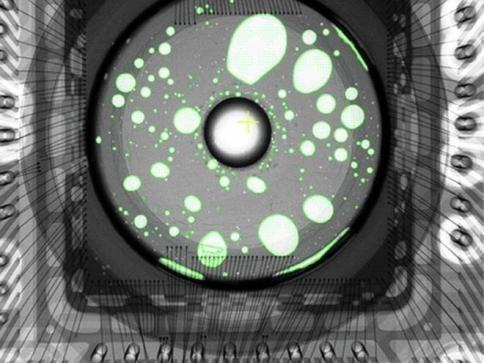

At present, many enterprises use X-ray inspection equipment analysis technology to analyze product quality, such as BGA welding point flow welding characteristics. For the inspection of non removable products, the shadow effect caused by solder or solder balls limits the operation of X-ray inspection equipment, making it unable to accurately reflect BGA process defects, such as bridging phenomenon.

To address these issues, technicians will use cross-sectional X-ray inspection technology to analyze solder joint defects. By focusing on the solder joints, the connection status of BGA solder joints can be revealed. If in the same situation, the actual situation may be hidden in the image obtained by X-ray inspection, mainly because the reflow soldering point solder is above, which forms a certain shadow on the image effect.

By using X-ray detection layering technology, the following parameters can be obtained:

The center position of the solder joint;

The center of the solder joint is located in the relative position of the image slice, which can indicate the positioning of the component on the printed circuit board solder pad;

Weld radius;

The welding radius strategy can indicate the corresponding number of welding points during the welding process;

Take several loop lines centered on the solder joint and measure the thickness of the solder on each loop line

Measurement of ring thickness and their various rates of change, displaying the distribution of solder within the welding point, using these parameters is particularly effective in distinguishing wetting, condition, and the presence of voids.

The error in the shape of the welding point relative to the circular ring

The roundness of the welding point shows the uniform distribution of the solder around the welding point, which reflects the alignment and wetting with the center when compared to the same circle.

Overall, the information and data provided by the above tests are crucial for determining the complete structure of the welding points and understanding the performance of each step in the BGA assembly process for X-ray layering.