Methods for improving the quality and efficiency of reflow soldering

Release time:2024-03-26Publisher:Jeenoce

1. Choosing the appropriate solder paste: The choice of solder paste has a significant impact on the quality of reflow soldering. Suitable solder paste should be selected based on the material, size, and welding requirements of components and circuit boards. The alloy composition, flux, viscosity and other parameters in the solder paste can all affect the welding quality.

2. Optimizing PCB design: Optimizing circuit board design can improve the soldering efficiency of reflow soldering. Reasonable layout of components, reducing the distance between components, and reducing the number of welding points can reduce the difficulty and time of welding.

3. Accurate control of welding temperature: The temperature control accuracy of reflow soldering equipment directly affects the welding quality. Suitable welding temperature curves should be set according to the characteristics of solder paste and components to ensure that the solder can fully melt and form good welding points.

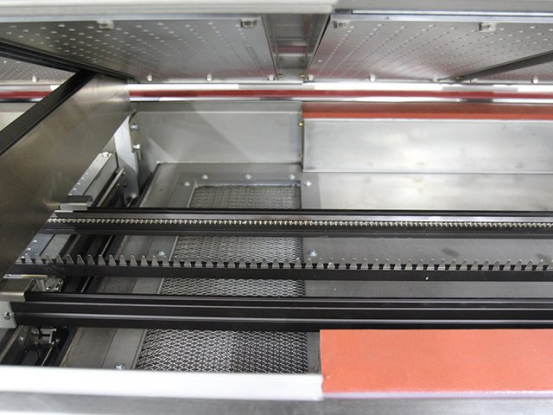

4. Maintain the equipment in good condition: Regularly maintain and clean the reflow soldering equipment to ensure its stability and reliability. Regularly inspect and calibrate key components such as temperature sensors and conveyor belts of the equipment to ensure normal operation.

5. Improve operational skills: Train operators to enhance their understanding and operational skills of reflow soldering technology. Operators should be proficient in equipment operation, parameter settings, and handling of anomalies during the welding process.

6. Adopting advanced reflow soldering technology: With the development of technology, new reflow soldering technologies such as full heat reflow soldering, laser reflow soldering, and optical reflow soldering continue to emerge. Choosing the appropriate reflow soldering technique according to needs can improve welding quality and efficiency.

7. Strict quality inspection: Conduct strict quality inspection on the soldered circuit board, and promptly repair or scrap any welding defects found. Quality inspection can use methods such as visual inspection, X-ray inspection, and automatic optical inspection (AOI).