What are the methods for factory inspection of BGA defects after packaging?

Release time:2024-03-26Publisher:Jeenoce

Production and processing factories often cannot guarantee the qualification rate of electronic components produced. The most important thing is that for packaging enterprises like BGA, the cost of simply relying on post packaging testing to improve product quality after BGA packaging is relatively high. Generally speaking, the current testing methods of factories mainly include:

1. Use a high-power magnifying glass to observe the defects of solder joints, but it is not possible to visually inspect the internal or obstructed solder joints;

2. Destructive sampling, using a sampling method to conduct relevant testing on the inspected product, is insufficient in that it needs to be disassembled for inspection, which may cause irreversible product damage to the product;

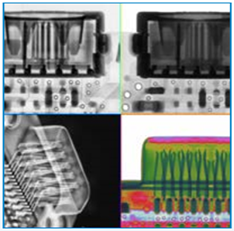

3. Non destructive testing. Currently, the main non-destructive testing methods in the market include X-RAY testing, magnetic particle testing, and ultrasonic testing. Among these three methods, X-RAY testing is the main one, which mainly relies on the principle of X-ray penetration to detect internal defects in the product. The X-RAY testing method is simple and direct, and can visually see whether the product has defects through the display, as well as the size of the defects and other data.