The practicality and benefits of dispensing machines

Release time:2024-03-15Publisher:Jeenoce

The dispensing machine is an automated equipment widely used in the manufacturing industry, which has high practicality and efficiency. JEENOCE will comprehensively introduce the practicality and benefits of dispensing machines, elaborating in detail on their working principles, application areas, advantages, and economic benefits.

operational principle

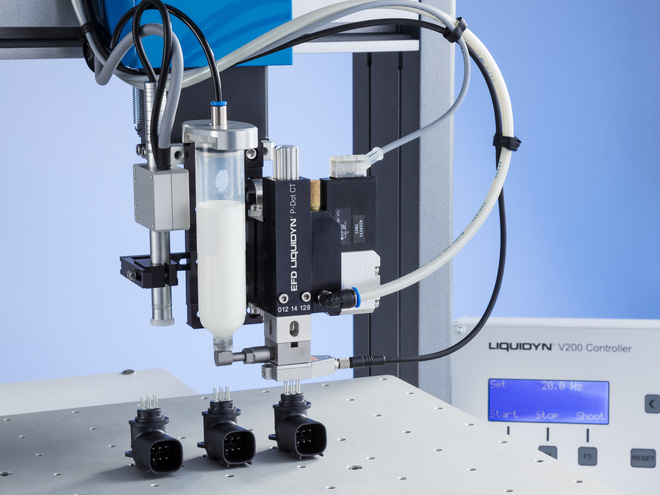

The dispensing machine is an equipment based on automation technology, which controls the dispensing process through a control system. Its working principle is to evenly squeeze the glue from the dispensing needle and apply it to the parts that need to be glued. The dispensing machine usually includes the main components of the glue supply system, control system, and dispensing head, ensuring the adhesive performance and bonding quality by accurately controlling the glue flow rate, speed, and shape.

application area

The dispensing machine is widely used in various manufacturing industries, covering multiple fields such as electronics, automotive, aerospace, medical equipment, etc. In the electronics industry, dispensing machines can be applied in processes such as semiconductor packaging, electronic assembly, and circuit board packaging to ensure precise bonding between electronic components. In the automotive industry, dispensing machines can be used for bonding automotive lighting fixtures, glass, sensors and other components, improving the sealing and durability of products. In the fields of aerospace and medical equipment, the application of dispensing machines is more extensive, including the application of precision adhesive points and the demand for high reliability bonding.

advantage

Compared to traditional manual dispensing, dispensing machines have significant advantages. The dispensing machine can efficiently and accurately distribute and apply glue, ensuring consistency in the quality of each adhesive point. The dispensing machine can be automated according to product requirements, reducing manual errors and workload, and improving work efficiency. The dispensing machine has a wide range of adaptability, which can adapt to different adhesives and perform bonding in different working environments, greatly improving production flexibility. The dispensing machine adopts an advanced control system that can monitor the glue supply and dispensing process in real time, thereby ensuring the quality of bonding and the stability of production.

economic benefits

The application of dispensing machines has brought significant economic benefits. The high efficiency, precision, and stability of the dispensing machine can greatly reduce the waste of glue and the rate of defective products, thereby reducing production costs. The dispensing machine can replace manual dispensing operations, reducing personnel demand and labor costs. The high-speed production capacity of the dispensing machine can improve production efficiency, increase output, and thus bring better economic benefits. The service life of the dispensing machine is relatively long, and the maintenance cost is relatively low, which reduces the cost of equipment maintenance and replacement and further improves economic benefits.