Advantages of X-ray testing equipment for detecting PCB boards

Release time:2024-02-29Publisher:Jeenoce

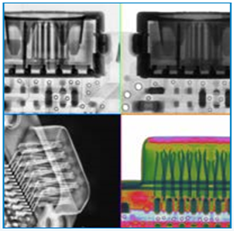

X-ray detection equipment uses X-RAY to penetrate the PCB board and obtain images on specialized imaging sensors, achieving perspective projection of the PCB board. It plays a very important role in solving the quality control of component packaging such as BGA and CSP.

According to AXI, it can be designed into two types: 2D/3D. When X-RAY light penetrates the sample, the absorption of X-RAY varies among different materials, especially since tin balls contain various materials such as tin and lead. These materials can absorb a large amount of X-rays, and the image obtained on the sensor is black, that is, a black image is formed at the solder joint of the tin ball. Technicians extract what they want from the image for analysis, To inspect the products to be inspected for any defects.

The advantages of X-ray testing equipment are mainly reflected in:

1. For processes with high defect coverage and the ability to simultaneously detect defects that cannot be observed by other detection methods, such as virtual soldering, false soldering, missed soldering, etc., especially for detecting hidden solder joints such as BGA and CSP;

2. Quick detection, for layered or multi-layer PCB boards, only one inspection is needed to complete defect detection for double-sided and multi panel boards;