Principle and equipment structure of dispensing machine

Release time:2024-02-26Publisher:Jeenoce

In modern industrial production, dispensing technology plays a crucial role and is widely used in various fields such as electronics, automobiles, medical equipment, etc. As a key equipment in dispensing technology, the principle and structure of the dispensing machine play a crucial role in achieving precise application of glue. Jinos Electronics will focus on introducing the principle and equipment structure of the dispensing machine, and delve into its application and significance in industrial production.

A dispensing machine is an automated equipment used for high-precision and high stability dispensing of glue in industrial manufacturing processes. Its principle is based on a series of precise control and execution systems, which can achieve accurate release of liquid glue and ensure controllability of glue application amount and speed.

1. Glue supply

The dispensing machine transports glue from the storage container to the dispensing valve through the glue supply system. The viscosity, pressure, and temperature of glue can all affect the quality and performance of dispensing.

2. Glue dispensing valve control

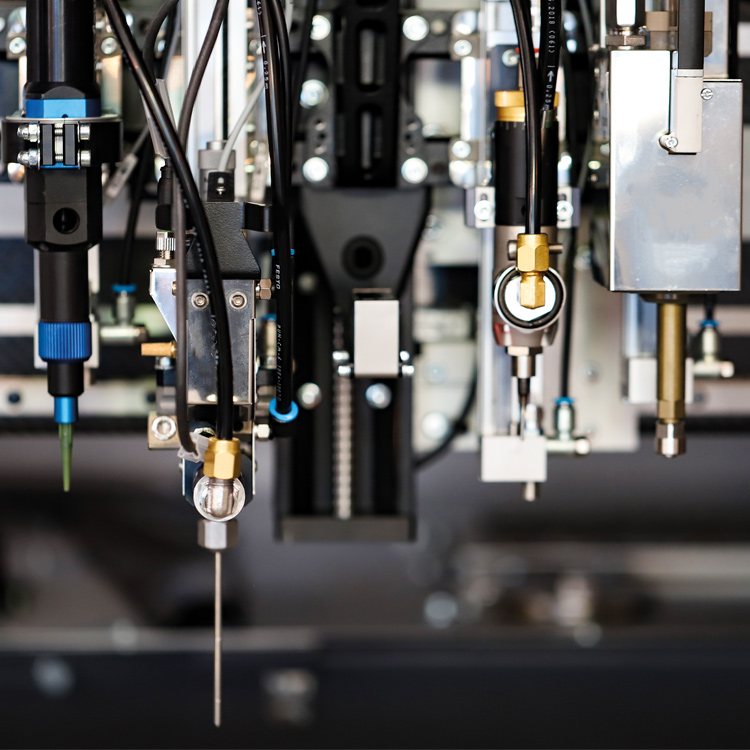

The dispensing valve is one of the core components of the dispensing machine, which controls the flow of glue. Common dispensing valves include manual valves, screw valves, pneumatic valves, and servo valves. By controlling the opening and closing of the valve, the dispensing machine can stop and flow the glue.

3. Motion control

The dispensing machine is equipped with a precise motion control system, which can control the movement trajectory of the dispensing head in three-dimensional space. This control ensures that the glue is accurately released in the predetermined position.

4. Trigger mechanism

The triggering mechanism is used to initiate the dispensing process. It can trigger the dispensing action based on preset conditions or external signals, ensuring that dispensing begins at the appropriate time.

The equipment structure of the dispensing machine varies depending on different manufacturers and applications, but the basic composition usually includes the following aspects:

1. Control system

Usually controlled by microprocessors or PLCs. These control systems can control the operation of the dispensing machine based on preset parameters, achieving glue release and motion trajectory control.

2. Human machine interface

An intuitive and user-friendly human-machine interface for operators to set parameters, monitor the dispensing process, and adjust parameters. This makes the operation of the dispensing machine more convenient and efficient.

3. Glue supply system

Responsible for transporting glue from the storage container to the dispensing valve. It includes glue buckets, hoses, pressure control devices, etc.

4. Glue dispensing valve and nozzle

The dispensing valve is the core component of the dispensing machine, which can achieve different dispensing effects through different types of valves and nozzles, such as linear, circular, square, etc.

5. Sports system

Composed of various transmission devices, it is used to control the movement trajectory of the dispensing head in three-dimensional space. The commonly used transmission methods include servo motors, linear guides, etc.

6. Trigger

Used to initiate the dispensing process, it can trigger the dispensing action based on preset conditions or external signals, ensuring that dispensing begins at the appropriate time.

In summary, through the introduction of the principle and equipment structure of the dispensing machine by Innos Electronics, we know that its principle is based on a precise control and execution system, ensuring the accurate release of glue. Its equipment structure includes control system, human-machine interface, glue supply system, dispensing valve and nozzle, motion system, trigger and other components, which work together to complete high-quality dispensing tasks.