The Method of PCBA Reliability Analysis and Testing

Release time:2024-02-22Publisher:Jeenoce

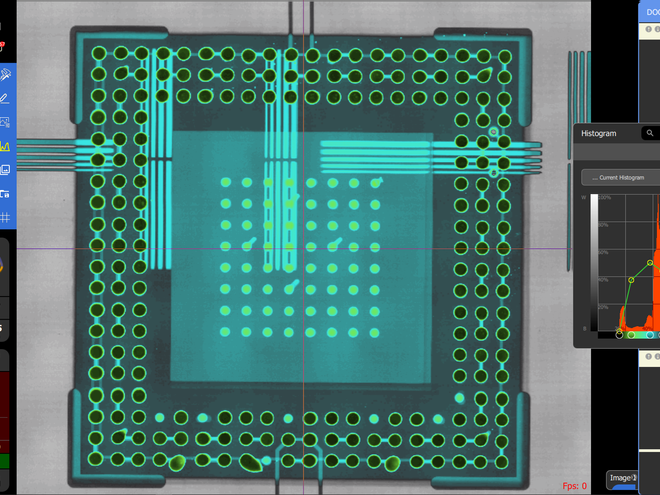

PCBA is the core component of electronic products, and its reliability directly affects the reliability of electronic products. The reliability of PCBA is largely determined by its welding quality. By analyzing common defects that affect the welding quality of PCBA, with the widespread application of surface mount devices such as BGA and CPS packaging, we need a new non-destructive method based on X-ray detection technology to detect welding defects that appear at the bottom of the device that are not visible solder joints, such as voids, short circuits, virtual soldering, misalignment, and PCB wire breakage.

The X-ray detection technology of PCBA is a new type of detection technology that has only emerged in recent years, as it can use non-destructive methods to detect internal conditions that cannot be observed by the naked eye or other detection equipment. Place the PCBA in the X-ray detection system and adjust the parameters such as voltage, power, and contrast of the detection system to achieve optimal imaging. The first step is to conduct a global inspection of the overall imaging of the PCBA, mainly including the PCB and all its components above it; The second step is to enlarge the image and perform local inspections in order, mainly to search for defects or suspected defects; The third step is to identify and analyze suspected defects through re magnification and oblique imaging; The final step is to focus on oblique imaging for BGA packaged devices, mainly checking for any solder defects.

PCBA often contains a large number of electronic components, ranging from a few to dozens, and they vary in size and packaging, leading to the possible presence of multiple welding defects in a single PCBA. When conducting defect detection, it is important to not miss a certain type of defect while also considering detection efficiency. Therefore, a reasonable detection process and engineering experience are very important. Analyze the characteristics and causes of various types of defects, and each step of testing should be targeted, with a focus on identifying specific types of defects.

A comprehensive and objective evaluation of the reliability risk of PCBA welding defects and the development of reasonable and standardized judgment standards can effectively prevent PCBA with reliability risks from being assembled in subsequent products, thereby avoiding huge losses caused by product failure.