Process requirements for reflow soldering

Release time:2024-02-20Publisher:Jeenoce

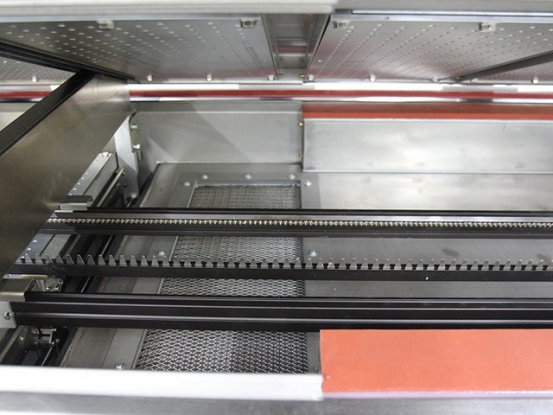

There is a heating circuit inside the reflow soldering equipment, which heats the air to a sufficiently high temperature and blows it towards the circuit board where the components have already been attached, allowing the solder on both sides of the components to melt and bond with the motherboard. The process requirements for reflow soldering are as follows:

1. The temperature of reflow soldering must be just right, as high or low temperatures can affect the soldering effect.

2. The time of reflow soldering is also important. If the time is too long, the solder will melt excessively, affecting the welding effect; If the time is too short, the solder will not completely melt and will also affect the welding effect.

3. The speed of reflow soldering is also important. If the speed is too fast, the solder will not completely melt and will also affect the welding effect; If the speed is too slow, the solder will melt excessively and also affect the welding effect.

4. In addition, reflow soldering also needs to consider the type and quantity of solder, and the welding effect will vary depending on the type and quantity of solder.

5. Reflow soldering also needs to consider the material of the circuit board, as different materials will have different effects on the soldering effect.

6. Reflow soldering also needs to consider environmental factors such as temperature, humidity, etc., which can also affect the soldering effect.