BGA packaging technology and solder joints of BGA components

Release time:2024-02-20Publisher:Jeenoce

The quality of solder joints is crucial for determining the reliability and performance of SMT components, therefore the quality of BGA solder joints should be a key focus. Therefore, it is crucial to take effective measures to ensure the quality of BGA components' solder joints in order to achieve the ultimate reliability of SMT components.

The limitation of fine pitch components is that their leads are prone to bending, breaking, and damage, which places high demands on the coplanarity and installation accuracy of the leads. BGA packaging technology adopts a new design thinking model, which hides circular or cylindrical solder balls below the packaging, resulting in larger lead spacing and shorter leads. Therefore, BGA packaging technology can solve the problems of coplanarity and warping that typically occur on fine-grained components.

Therefore, the reliability of BGA components and the performance of SMT components are superior to ordinary SMD (surface mount devices). The only problem with BGA components is that they are difficult to perform solder joint testing, making it difficult to ensure quality and reliability.

Therefore, common issues include solder joints in BGA components

So far, reliable electronic assemblers, such as PCBCart and BGA components, have been exposed through electronic testing. Other methods used to control the quality of assembly technology and identify defects during the assembly process of BGA components include slurry screening, AXI sample testing, and electronic test result analysis.

Meeting quality assessment requirements is a challenging technique as it is difficult to pick up test points under packaging. In BGA component defect detection and identification, electronic testing is usually not possible, which to some extent increases the cost of defect elimination and rework.

In the BGA component defect detection process, electronic testing can only determine whether the current is on or off after connecting the BGA component. BGA component assembly is a basic physical connection technology process. In order to confirm and control the quality of technical processes, it is necessary to know and test physical components to affect their long-term reliability, such as solder paste amount, lead and pad alignment, and wettability.

BGA component inspection method

It is very important to test the physical properties of the solder joints of BGA components and determine how to continue to contribute to reliable connections during the process research. The feedback provided by all tests is related to the modification of each technical process or solder joint parameter.

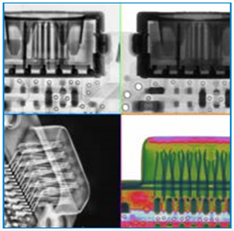

The X-ray inspection will apply this equipment, and the solder paste on the solder pad represents a shadow image, as the solder paste is located above the solder joint. For non foldable BGA components, shadows may also appear on the solder balls on the front, which undoubtedly makes identification difficult. This is because the shadow effect caused by solder paste or pre solder balls hinders the operation of X-ray inspection equipment, and X-ray inspection equipment can only roughly reflect the process defects of BGA packaging. In addition, peripheral inspections also face challenges such as insufficient solder paste or open circuits caused by pollutants. X-ray examination technology can overcome the above limitations. It can check for hidden defects in solder joints and display the connection of BGA solder joints.