What are the applications of double-sided coating machines in the toy industry?

Release time:2024-02-19Publisher:Jeenoce

The wide application of double-sided coating machines in the industry is unclear to many people. Today we will mainly talk about the application information of double-sided coating machines in the toy industry. The toy industry involves many adhesive fields, such as circuit boards, toy frame packaging, luminous powder epoxy resin, and so on. All of these require the use of adhesive, and using double-sided coating machines for processing is very promising in the toy industry. Domestic toy manufacturing has been sold in large quantities abroad, and it is difficult to meet the requirements of toy dispensing using traditional techniques.

The glue used in the double-sided coating machine varies at different positions, and the glue used for toy dispensing and packaging is different. However, different types of adhesives can be used in the double-sided coating machine.

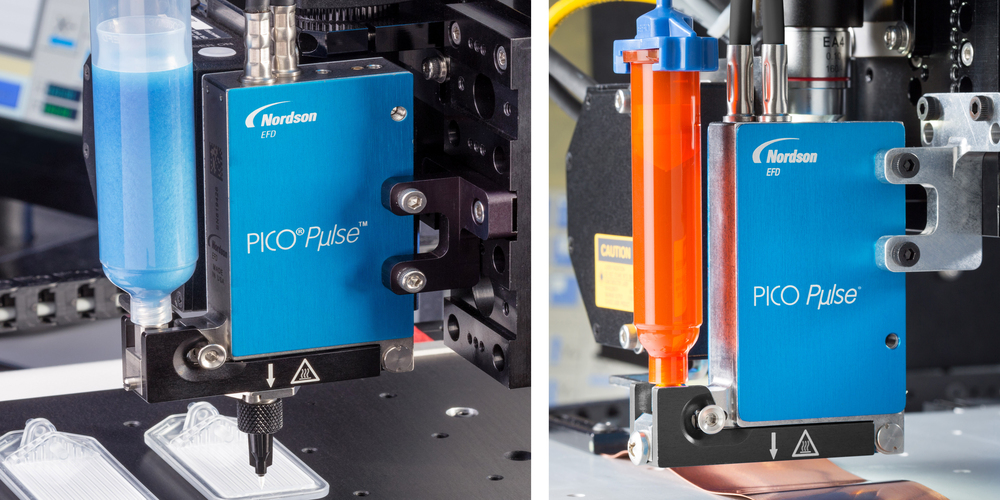

The double-sided coating machine, also known as the glue applicator, glue applicator, and drip applicator, can be seen from the use of luminous powder to mix glue and dispensing equipment to control the fluid. Why is this production method used for dispensing toys? Modern toys have increasingly high technological content, and the use of primitive manual glue cannot meet production requirements. The main reason is that the speed is relatively poor and it is difficult for companies to recruit. Currently, domestically produced glue dispensing equipment has a high cost-effectiveness, so these equipment are chosen for production.

After the application of double-sided coating machines in the toy industry, the cost of traditional manual dispensing has been greatly reduced. Due to the meticulous processing in the toy industry, it usually takes 2-3 months to cultivate a skilled employee. The operation of the double-sided coating machine is relatively simple, with fast dispensing speed and high accuracy. Moreover, due to the use of high-precision intelligent control, there will be no problems such as glue droplets and leaks during the packaging process, which is not a problem in basic dispensing in high-precision industry. Of course, not every position of a toy requires dispensing technology, it is only used for circuit boards, chips, and sealing glue.