How to handle the unstable or incorrect dispensing volume of the dispensing machine, and how to ensure the dispensing effect

Release time:2024-02-04Publisher:Jeenoce

Methods to solve the problem of unstable and malfunctioning glue output of the dispensing machine, small tips and formal operating methods for controlling glue output of the dispensing machine, factors affecting glue output of the dispensing machine, how to deal with glue errors that occur during use, steps for adjusting glue output of the dispensing machine, and methods to improve accuracy.

What is the reason for the unstable glue output of the dispensing machine? The dispensing machine brings convenience and efficiency to everyone, but it is inevitable to encounter various problems. If not resolved in a timely manner, it will affect work efficiency. Most of the air pressure is unstable, the glue is unstable, and the amount of glue produced is unstable. Unstable air pressure can lead to unstable dispensing accuracy, resulting in errors and leaks. At this time, a regulator or a pressure control valve can be equipped to stabilize the glue output and check the glue output time. The longer the dispensing time, the more stable the dispensing. Unstable glue: This is reflected in the difficulty of dispensing glue, weak fluidity, and wire drawing. This problem is generally due to the use of high viscosity glue. Measures can be taken to delay closing the glue: As the name suggests, after closing the glue head, there is still glue between the outlet of the glue head and the glue valve that has not been completed. Delay for a period of time, wait for the glue to flow out, and then perform subsequent actions.

Elevating height refers to moving empty to the starting point of the next trajectory after the dispensing of glue on one trajectory is completed. In this space, raise the glue head a little higher at the end point to ensure its safety and avoid hitting the needle, and then move it to the starting point of the next trajectory. Unstable glue output: mainly caused by unstable pressure cylinder or air pressure for storing fluid. The longer the dispensing time, the more stable the dispensing. Formal operating skills: The problem with the operation of automatic dispensing machines is the effectiveness of dispensing. The quality of dispensing products is directly related to the control of dispensing volume. In addition to setting parameters, the maintenance of automatic dispensing machines is also inevitably related.

There are several reasons for the poor control of the dispensing amount of the automatic dispensing machine. One reason is insufficient tracheal pressure, and the control effect of glue output is not significant. The second issue is that the leakage and glue output are too small. The third reason is that the second use of the dispensing needle causes blockage. The air pressure for automatic dispensing should be controlled within an appropriate range, and there should be no overpressure or low-pressure. If the air pressure is not within the required range, it is easy to cause a difference in adhesive output. The main reason is that the pressure tank of the dispensing machine is unstable, resulting in insufficient air pressure.

The main reason for dripping during dispensing by the dispensing machine is insufficient glue concentration, which causes the glue to flow down the needle during dispensing. As long as the vacuum suction function is added, a certain pressure difference between the internal and external atmospheric pressure of the dispensing valve can be utilized to close the dispensing valve and achieve control of the dispensing amount. In order to improve the control of glue output, it is necessary to maintain the dispensing machine. If it is necessary to use an automatic dispensing machine to complete special circular arc dispensing, in addition to controlling the dispensing amount, it is also necessary to program the circular arc path through the dispensing controller to improve the dispensing quality. Long term dispensing can affect the repeatability accuracy of the circular arc path, so maintenance and adjustment of the automatic dispensing machine can improve the quality of circular arc dispensing.

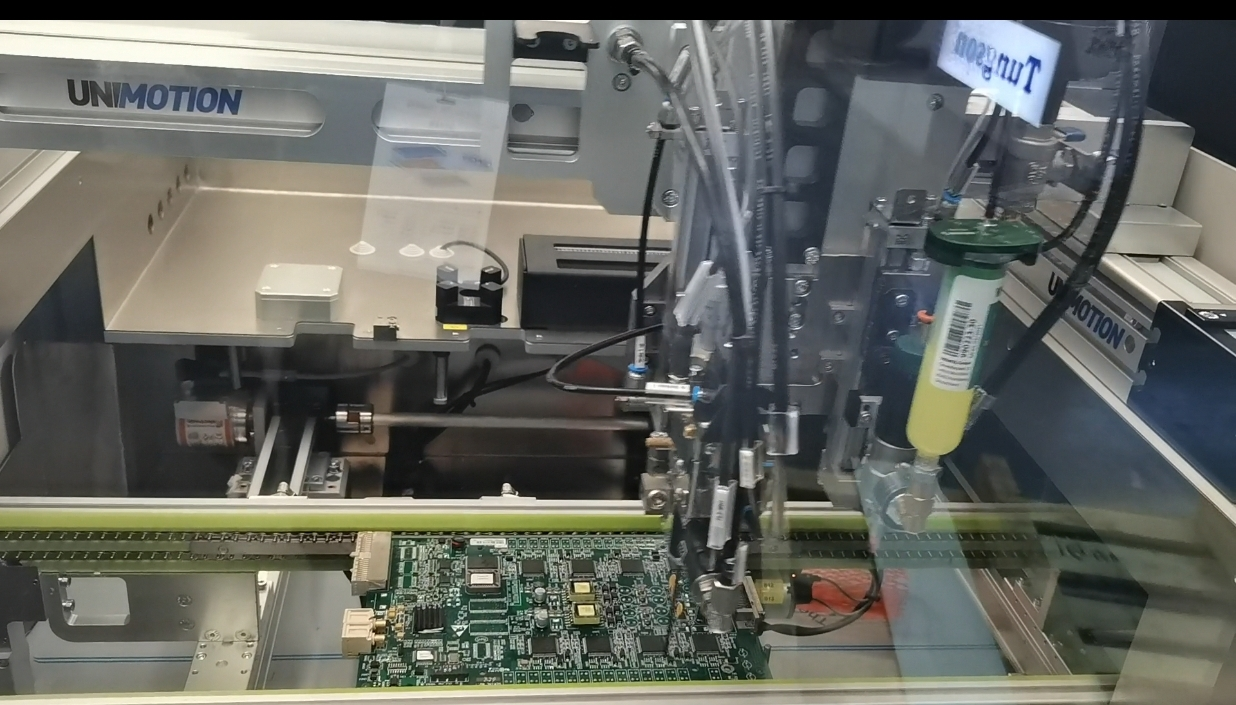

There are three factors that affect the control of dispensing machine quantity: many places in the electronic manufacturing industry require professional equipment for dispensing and sealing treatment. When dispensing, the distance between the dispensing needle and the circuit board and the inner diameter of the needle are the most important parameters. If the distance between the needle and the substrate is incorrect, the operator will never be able to obtain the correct dispensing result. When other parameters remain unchanged, the larger the distance between the dispensing needle and the circuit board, the smaller the point diameter, and the higher the point height; The smaller the distance between the dispensing needle and the circuit board, the larger the dot diameter, and the lower the dot height.